Are you involved with 3D printing of metal powders, but only need a small quantity of powder? Did you get a quote, and the minimum order would potentially last you until your next lifetime? If you are interested in an alternative that allows you the freedom to make small quantities of powder yourself, of alloys of your choosing in tailored particle sizes, with the added benefit of being able to recycle any waste powder, read on.

Gas Atomisation

Gas atomisation is the traditional method for producing metal powders and is excellent for producing large quantities of material. The process involves melting a metal in a crucible or similar vessel. Once the melt has been homogenised, the molten metal flows down to a refractory nozzle. Upon exiting the nozzle, the stream of molten metal is hit with a jet of high-pressure inert gas such as nitrogen or argon which turns the metal into droplets, which solidify to form metal powders. The entire process is typically carried out under an inert atmosphere to prevent oxidation.

While the process is extremely effective, it generally involves large scale production, of the order of 50kg plus and is not geared up to produce small batch orders in the sub 5kg realm. Furthermore, there are significant time and costs involved in changing alloy compositions which can drive the price of small orders into the stratosphere as well as requiring extended lead times.

Evolution of Ultrasonic Atomisation

In 2016, Łukasz Żrodowski as a Ph.D student needed 200g of powder. A batch of this size was simply uneconomical to produce by gas atomisation, and so he went on the hunt for a way to produce small quantities of spherical metal powders.

In the process he rediscovered the ultrasonic atomisation process that had been dormant for the past 40 years. Over the subsequent years he repurposed the technology and refined the process to suit his requirements while at Warsaw University of Technology.

In 2019, Łukasz founded AMAZEMET and all the ultrasonic atomisation IP and other expertise for support removal was transferred to them. Since then, AMAZEMET have been supplying rePOWDER, a laboratory scale ultrasonic atomisation system for in-house manufacturing of powders and devices for the post-processing of printed parts such as inFurner high vacuum furnace for heat treatment and safeEtch device for automated support removal.

The Ultrasonic Atomisation Process

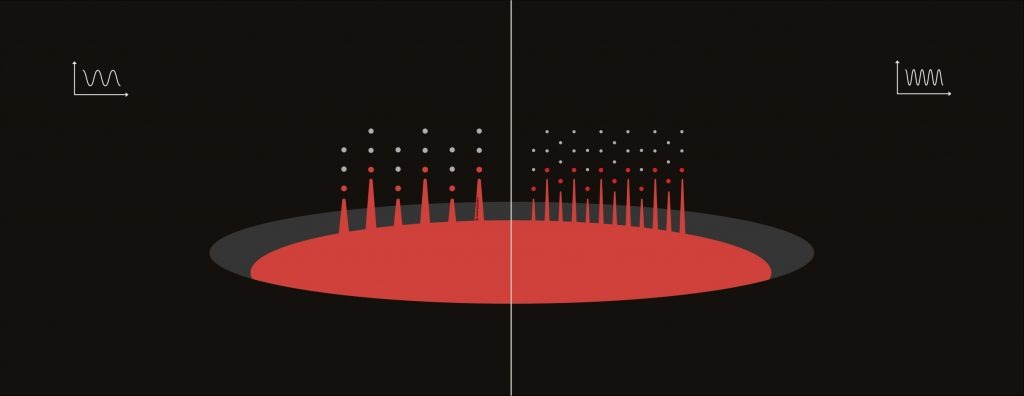

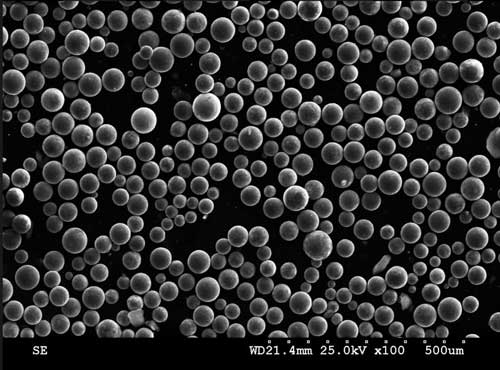

The ultrasonic atomisation process involves pouring a stream of molten metal onto a vibrating part, called a sonotrode. This causes tiny metal droplets to be ejected from the surface. In doing so, they solidify in the surrounding inert atmosphere, producing spherical metal powders with very narrow particle size distributions. The actual particle size of the powders, while dependent on the alloy composition can be controlled by the frequency of vibration of the sonotrode, with higher frequency vibrations leading to smaller particle sizes.

The AMAZEMET rePowder system offers the option to use an induction furnace for alloys with melting points below 1300°C, or an arc/plasma furnace that caters for alloys with melting temperatures up to 3500°C. To date there are over 30 installations around the world, including several in the USA and China.

Key Benefits of Ultrasonic Atomisation

For those looking to produce their own metal powders for AM and other processes, ultrasonic atomisation has many benefits:

- Suitable for any alloy composition – The process suits anything from pure elements to exotic and refractory alloys

- Any form or feedstock – Suited to any form e.g. chips, failed AM prints, damaged samples, rods, wire, powder, etc.

- Controllable particle size – Particle size a function of sonotrode vibration frequency and amplitude as well as alloy composition

- Low running costs – Relatively low gas consumption, comparable to TIG welding, typically in the range of 8-15 l/min

- Variable capacity – Run batches from just a few grams to multiple kg per day

- Recycling – Reprocess printed or failed parts or even scrap material

- Modularity – Add new modules at any time to expand capabilities

- Versatility – Prepare new compositions, alloy homogenisation, ultrasonic atomisation, suction casting and further options in development

- Multiple alloys in one day – Easily clean and modify the instrument to produce multiple alloys

The flexibility of the process makes it ideal for alloy prototyping and refining of alloy compositions. In addition, its ability to deal with a wide variety of feedstocks makes it ideal for recycling left over powder from processes metal additive manufacturing processes like Laser Powder Bed Fusion (LPBF), Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) or even failed parts.

Powder Properties

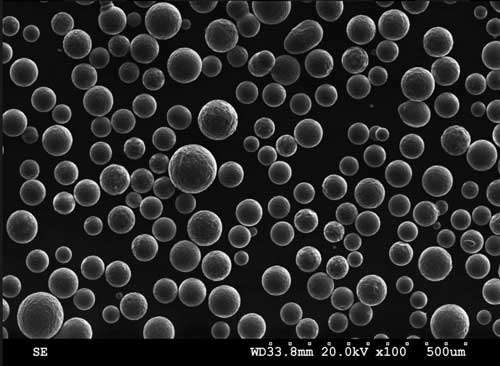

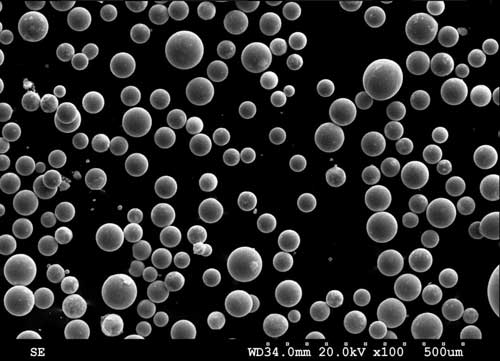

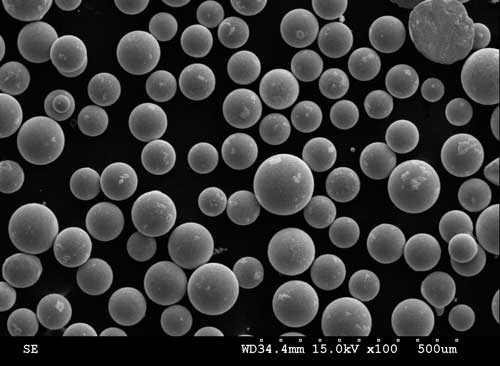

Ultrasonic atomisation produces metal powders with unrivalled sphericity, up to 0.98. By ensuring the frequency is kept constant, the particle size distribution remains very narrow. The vacuum tight processing chamber keeps oxygen content below 100ppm preventing unwanted oxidation.

The tight control over particle size also benefits AM processors by facilitating a more consistent and repeatable process, while the high degree of sphericity encourages even flow and packing of powder beds. If the metal powder consisted of particles of different sizes, the laser would interact with the different sized powder particles differently, which will result in different degrees of melting, influenced by the particle size.

Gas Atomisation vs Ultrasonic Atomisation

Table 1. Head-to-head comparison of gas and ultrasonic atomisation processes.

| Process | Gas Atomisation | Ultrasonic Atomisation |

|---|---|---|

| Particle morphology | Various shapes | High sphericity |

| Particle size distribution (PSD) | Wide | Narrow |

| Throughput | High – suits industrial scale | Low – ideal for laboratories |

| Powder yield | Moderate | High |

| Flexibility | Poor | Excellent |

| Equipment size | Enormous | Compact |

| Feedstock | Any | Any |

| Inert gas consumption | High | Low |

Applications

While primarily developed for producing powder for AM, ultrasonic atomisation technology is equally at home generating feed powders for cold spraying, thermal spraying, catalysis, powder metallurgy processes and any other application requiring spherical metal powders. It has also been shown to be compatible with almost any metal alloy, pure metals as well as some metal matrix composites (MMC) and semi-metals.

Instrument Features

The thoughtfully designed system can be installed into a small space, requiring only a few square metres, including associated infrastructure. The sealed working chamber permits oxygen-free processing while rePowder comes pre-programmed with recipes for many basic materials to help you get up and running in the shortest possible timeframe.

The easy clean design prevents powder adhesion and facilitates metal losses and contamination, while accurate temperature control prevents evaporation of alloy ingredients such as Cu or Sn.

The system itself is modular and can be tailored to the needs of the client i.e. the types of feedstocks that are going to be processed. In addition, this design allows you to add more modules down the track.

Feedstocks

The rePowder system is extremely flexible. As mentioned, it can be equipped with either an induction furnace or arc/plasma furnace depending on the melting point of the alloys you are working with. It can also be adapted using purpose-built modules to work with a range of feedstocks of almost any composition including:

- Rods and bars with round, square or irregular cross-sections

- Wire – round or square from 0.8 to 2.0mm

- Homogenised or cast ingots, buttons and irregular shapes

- Powders

- Scraps, leftovers and samples e.g. from mechanical testing

Summary

Metal powders have many applications such as additive manufacturing and thermal spraying. For those involved in research, alloy prototyping etc. where only small quantities are required, or custom formulations that are uneconomical to source from the traditional channels. Using systems like the rePowder from AMAZEMET you can now produce small batches of powder from tens of grams up to several kilograms using ultrasonic atomisation technology in your own lab. This system has been proven to work with most alloys and elements where it produces highly spherical powders with tight particle size distributions and excellent flow properties from any feedstock, including waste powder from LPBF and related processes.