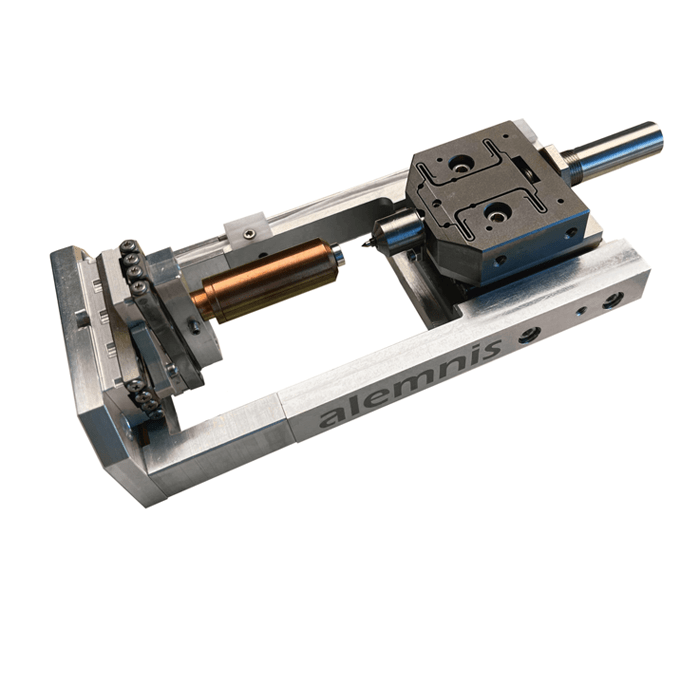

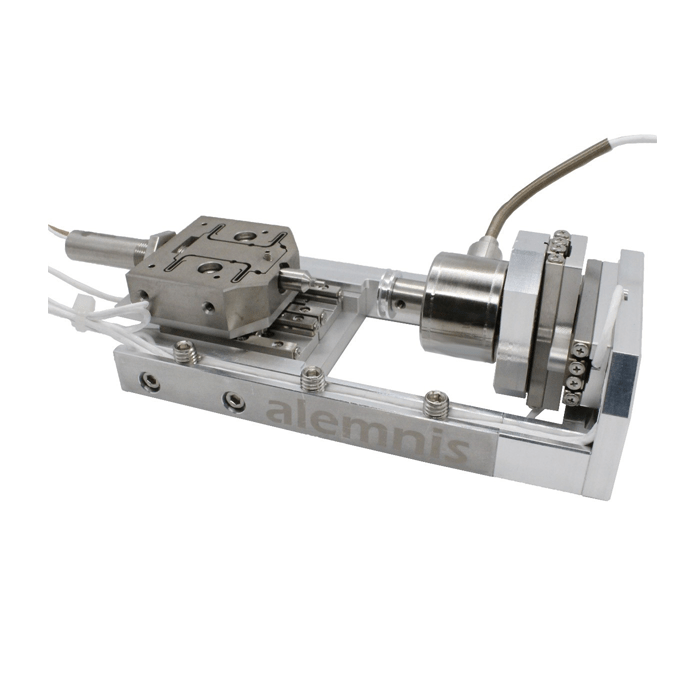

Ultra High Strain Rate (UHS) Module

In situ

Pushing the frontiers of nanomechanical testing

High-precision nanoindenter that can be customised with a range of accessories, consumables and controllers

Designed and built by the nanoindentation originators, the Alemnis’ ASA Nanoindenter features a unique modular design that can be easily customised to your specific requirements using a vast array of accessories, making it extremely versatile as well as being extremely cost effective. It can be used in a variety of instruments, many of which allow micro and nanoscale imaging in real-time. As such, the ASA Nanoindenter is used in many of the world’s most prestigious research institutions.

The Alemnis ASA Nanoindenter affords you the freedom to operate in any number of configurations including:

The ASA enables the testing of materials in a vast array of environments with options including:

The versatility and valuable data produced by the Alemnis ASA Nanoindenter provide insights for numerous industries such as:

It generates data for this wide variety of industries via numerous test methods such as:

Run time – 2:26min

Short video demonstrating the entire process after installation including:

Other examples shown are a quasi-static pillar compression test and a fatigue test (cyclic oscillation).