Non-destructively see in inside your AM parts

Additive Manufacturing (AM) is becoming an increasingly important production technique for safety critical aerospace parts. Often these parts are very complex and require new methods of testing to ensure their structural health and integrity. Furthermore, with more than 50 parameters influencing the outcome of the final part, AM remains a constant challenge.

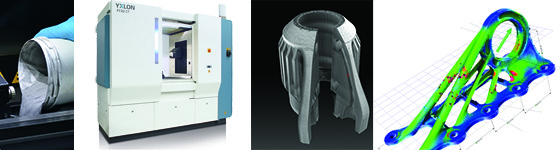

Computed Tomography (CT) with powerful software is the most superior inspection technique available for AM. They can be used throughout the entire workflow from analysis of powders, to melt pool analyses to inspection of the final part for anomalies such as porosity, cracks, inclusions or remaining powder that must be detected.

CT data is comprehensive in that it non-destructively represents the full 3D volume of the parts. This covers not only the outer surface, but the complete part including the inner structures. This capability makes it ideal for guaranteeing safe operation, by verifying wall thicknesses or internal dimensions e.g. the inner diameter of a cooing channel

Different application examples will be presented to show the challenges, problems and typical defects that may be present in AM parts. In the process we will demonstrate the ability of CT to non-destructively separate flawless parts from defective ones. The impact on process improvement will also be shown.

Watch the webinar