MicroCT with its ability to non-destructively image materials in 3D is arguably the most exciting imaging modality in materials science. While some systems are able to carry out time lapse studies, TESCAN have upped the ante with the ability to perform dynamic CT experiments, i.e. long-term continuous scans.

Through a marriage of high-power X-ray source, fast detector and powerful software, the TESCAN DynaTOM achieves a spatial resolution of 2-3µm and temporal resolution of 10 seconds. This allows true time-resolved microCT or 4D CT studies that reveals changes to extremely fine structures as they happen.

With a unique gantry-style architecture, experimental apparatus can be easily incorporated into the X-ray chamber. These allow you to observe changes in materials under dynamic conditions such as load, temperature, flow etc. With the continuous scanning capability, you won’t miss any critical events as may be the case with time lapse. In doing so, you can replicate real life service conditions to see how your material or components will perform in operation, thus accelerating your path to commercial success.

This technology is ideally suited to the development of advanced materials and structures as well as systems in life science and geological sciences.

On-Demand Webinar

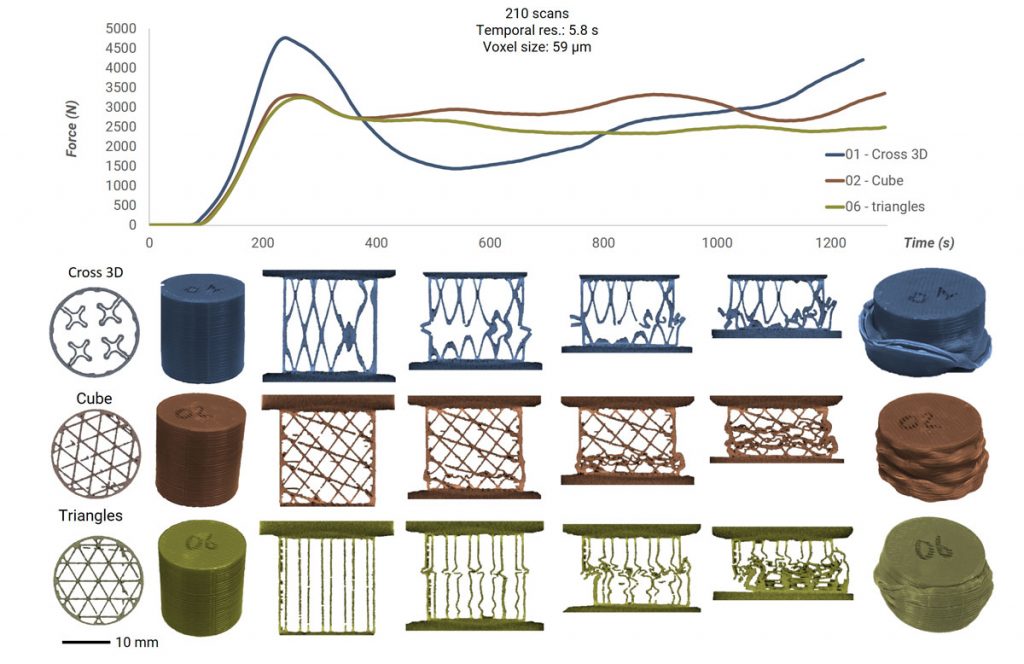

Additive manufacturing (AM) has grown tremendously in recent years, revolutionising the traditional manufacturing landscape. However, there are still a number of hurdles to overcome concerning the quality of the final part.

This on-demand webinar looks at how dynamic microCT is being used by the additive manufacturing industry to develop and refine the processes.