On-Demand Webinar

TESCAN’s new TENSOR 4D-STEM is revolutionising how materials can be characterised at the nanoscale. By designing the system from the ground up for performance and usability, precise, multimodal 4D-STEM structural and analytical measurements are within the reach of all users and are not limited by conventional TEM designs.

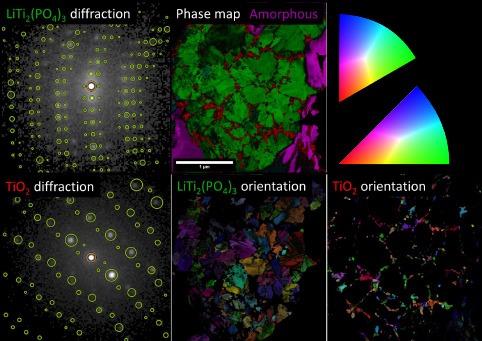

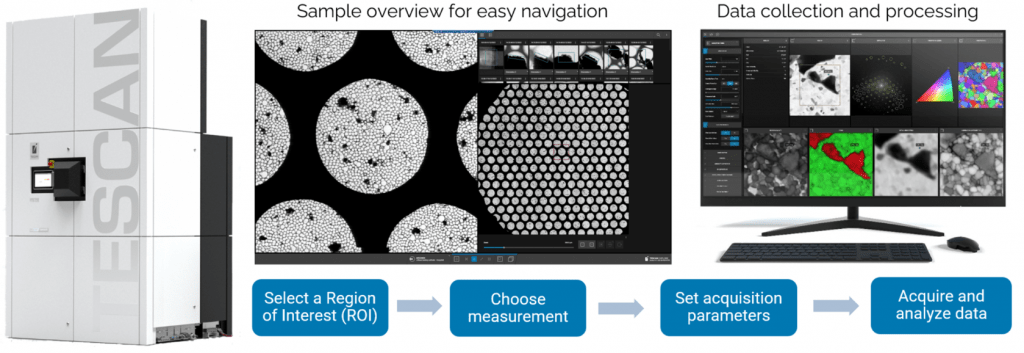

Full integration and synchronisation of state-of-the-art components such as a large direct electron detector with hybrid pixel technology, electron beam precession, electrostatic beam blanker and large dual EDS detectors maximises throughput of STEM, EDS and 4D-STEM measurements. The included ExploreTM software package streamlines workflows allowing data acquisition, analysis and visualisation in almost real-time resulting a optimised user expereiences.

Furthermore, a novel approach to analytical STEM measurement allows users to generate STEM, 4D-STEM, EDS and tomographic data as if they were using a SEM or FIB/SEM, unlike other approaches that rely on complex TEM training. This opens doors for nanoscale research in multimodal, nanoscale morphological, chemical, and structural characterisation of functional materials, thin films, and synthetic and natural crystals.

Agenda

- Introduction

- Nanoscale characterisation by analytical STEM

- New approach to precession-assisted 4D-STEM

- Analytical STEM capabilities of TESCAN TENSOR

- Technology behind TESCAN TENSOR

- Improvements of analytical STEM measurements (link)

- Improved performance at 100kV without sample limitations

- Improved quality of diffraction data by beam precession

- Improved speed of precession-assisted 4D-STEM data acquisition

- Improved time to results by on-the-fly data processing and analysis

- Improved usability and reproducibility by automation and setting presets

- Improved accuracy of measurements by multimodal 4D-STEM/EDS data

- Improved diffraction tomography (3D-ED) by beam precession and 4D-STEM

- TESCAN TENSOR in a nutshell

- Demonstration of capabilities (pre-recorded)

Presenter – Dr. Daniel Němeček

TESCAN GROUP, Czech Republic

Daniel has 15+ years of hands-on experience with analytical and structural techniques in both academia and industry settings. He worked with R&D teams and product managers to ensure customer needs were realised during the development of the TENSOR.