Additive manufacturing is experiencing significant growth in Australia. As such AXT are pleased to announce that they will now be representing Aconity3D, making their metal 3D printing systems available to academic and industrial researchers in Australia and New Zealand and further strengthening their range of additive manufacturing solutions.

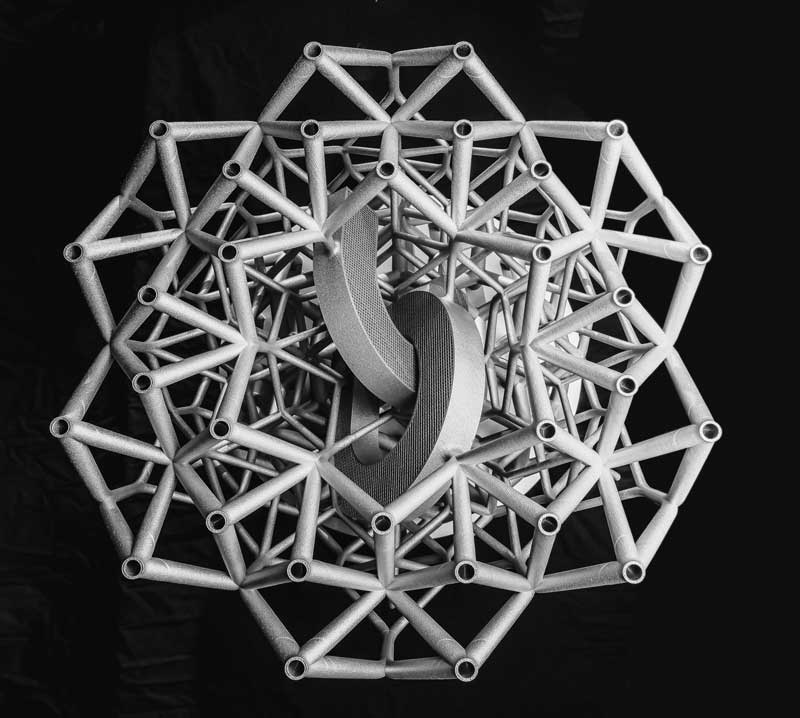

Aconity3D, established in 2014 have developed extensive expertise in powder bed laser melting, for the 3D printing of metal components using any weldable metal or alloy. They offer a range of systems produced with the engineering precision you would expect from a German manufacturer. Their modular design allows clients to customise each system to their particular needs with systems installed around the world servicing industries such as aerospace, automotive and medical.

They have larger systems suited to printing of large components on an industrial scale with a building platform of 400mm diameter with four lasers for maximum productivity down to compact systems, ideal for production of small parts or rapid prototyping. Their systems incorporate innovative features developed in house such as automated powder refilling systems with built in sieving stations and revolutionary vibrating powder deposition to ensure you get the best possible component quality.

AXT’s Managing Director Richard Trett commented, “we are delighted to partner with Aconity3D. Australia is a nation that will prosper based on advanced manufacturing and being able to offer cutting-edge solutions like Aconity3D’s metal 3D printers will help us fulfil a need in the local market. The addition of their products to our portfolio also further strengthens our additive manufacturing offering.”

Dr. Yves Hagedorn, Managing Director at Aconity3D responded, “we are extremely happy partner with AXT and we feel confident that AXT can help us replicate the success we have had in Europe on the other side of the world.”

For more details on Aconity3D’s 3D metal printers, click here.