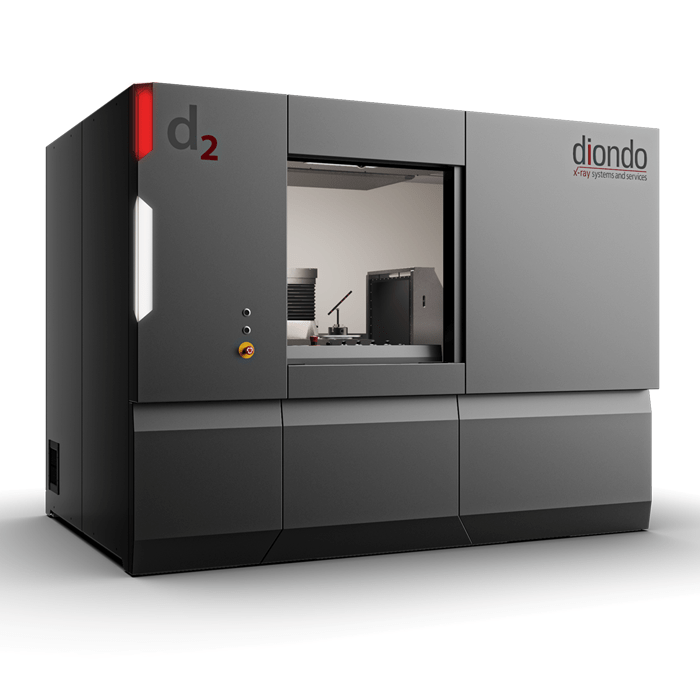

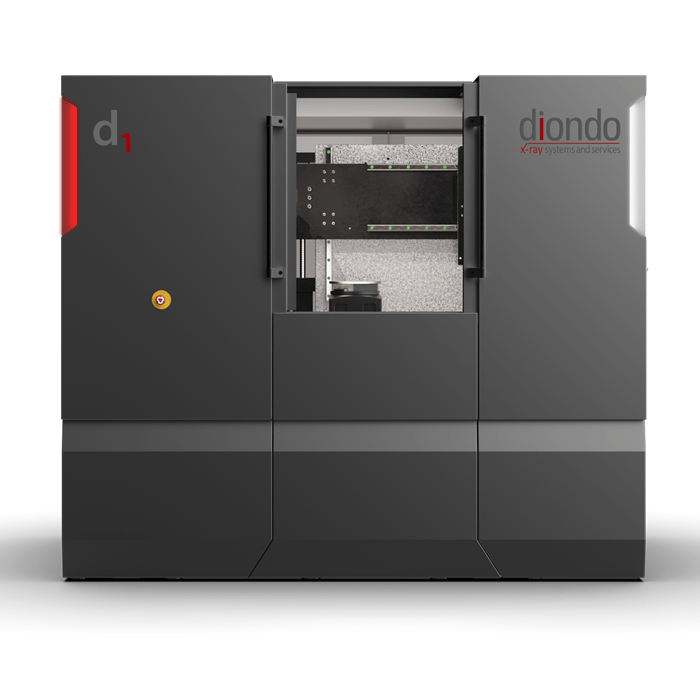

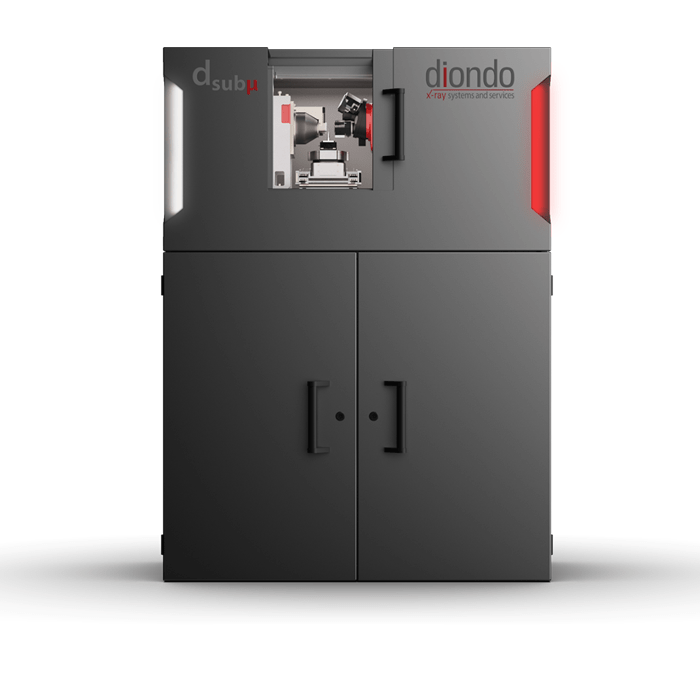

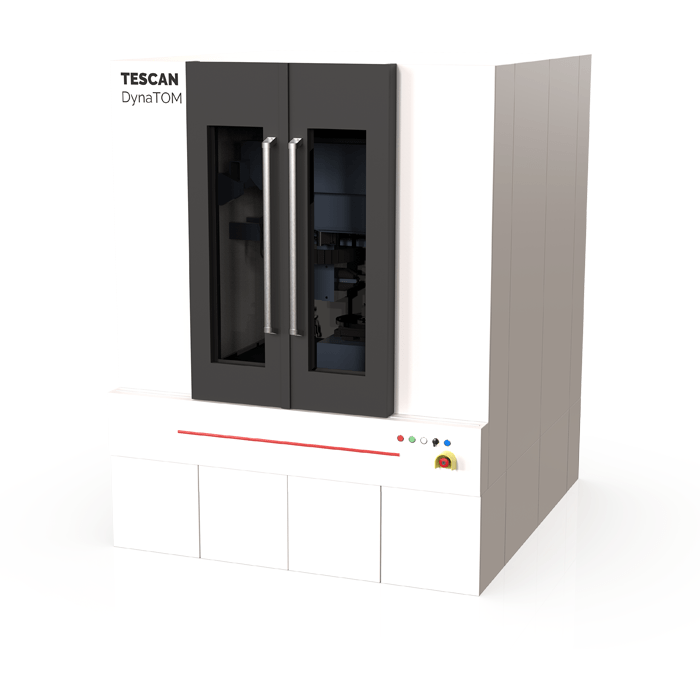

AXT offers a wide range of Computed Tomography solutions including turnkey systems from diondo, TESCAN, Rigaku and Sigray or we can build bespoke system to suit your exacting requirements.

Computed Tomography or CT is a rapidly growing field that caters for everything from Quality Control (QC) through to high-end research. This growth is largely being lead by the advanced manufacturing sector and additive manufacturing. In days gone by, QC may have involved sacrificing one components from a large batch that was viewed as representative of the batch. More recently, additively manufactured components can be highly intricate and it may be uneconomical to sacrifice a part, and hence, computed tomography becomes a highly effect tool for QC to avoid premature failure in mission critical components, such as those used in aerospace applications.

Computed Tomography is a 3D inspection technique that is an extension of radiography (2D) or X-ray inspection that has been used extensively in non-destructive testing (NDT). Systems are now specifically designed for the rigors of industriral and materials applications, while early work in these fields was carried out using medical systems, often called CAT scanners.

Why do you need a Computed Tomography Solution?

Computed Tomography is used for many reasons such as:

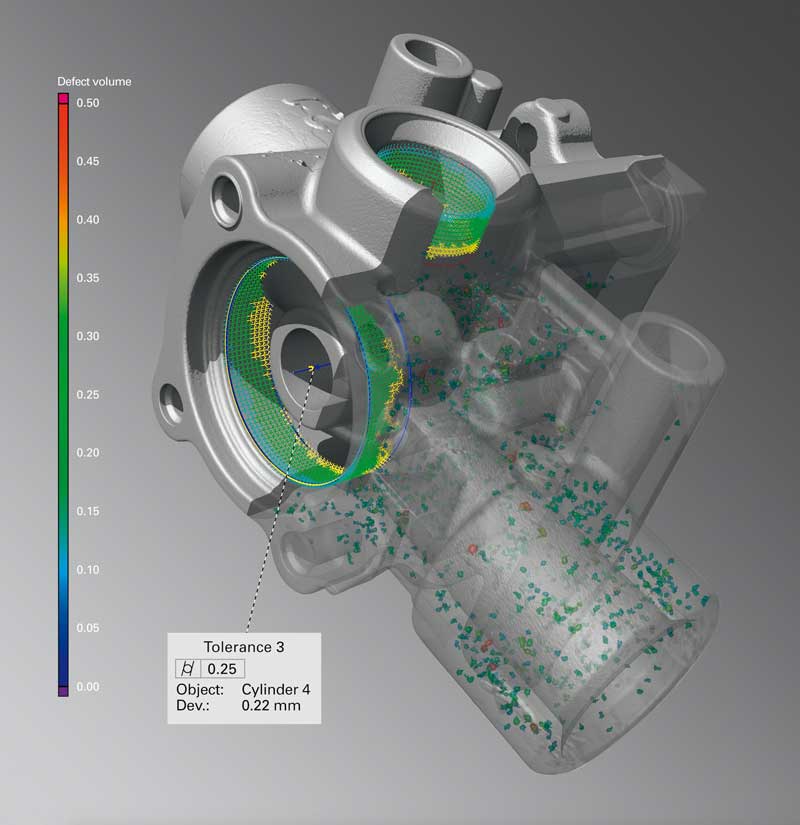

- Flaw detection including pores, cracks, voids and other defects

- Assembly analysis

- Metrology including wall thickness determination, cyclindricty of holes and checking if other dimensions are within design tolerances

- Failure analysis

- Reverse engineering

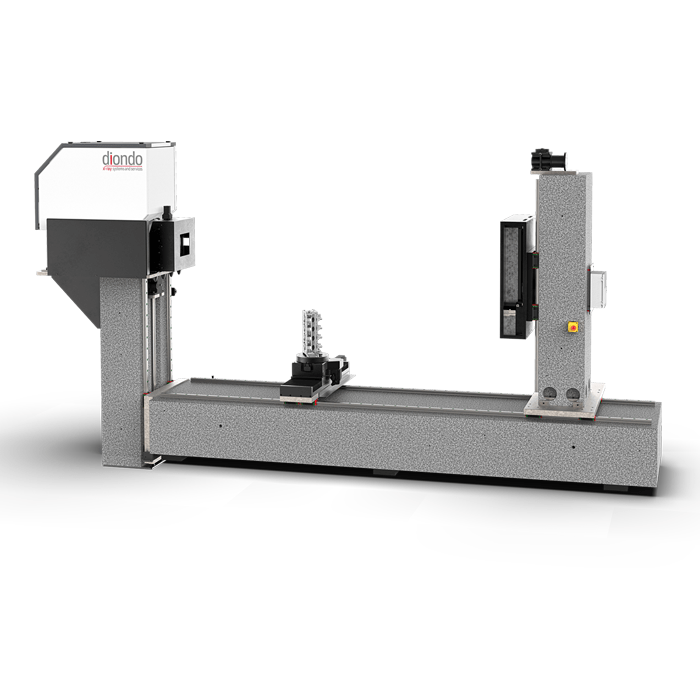

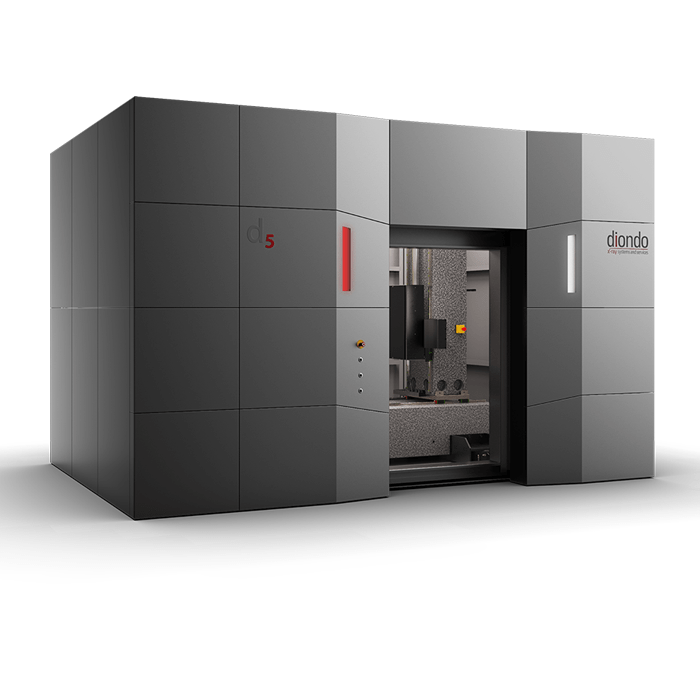

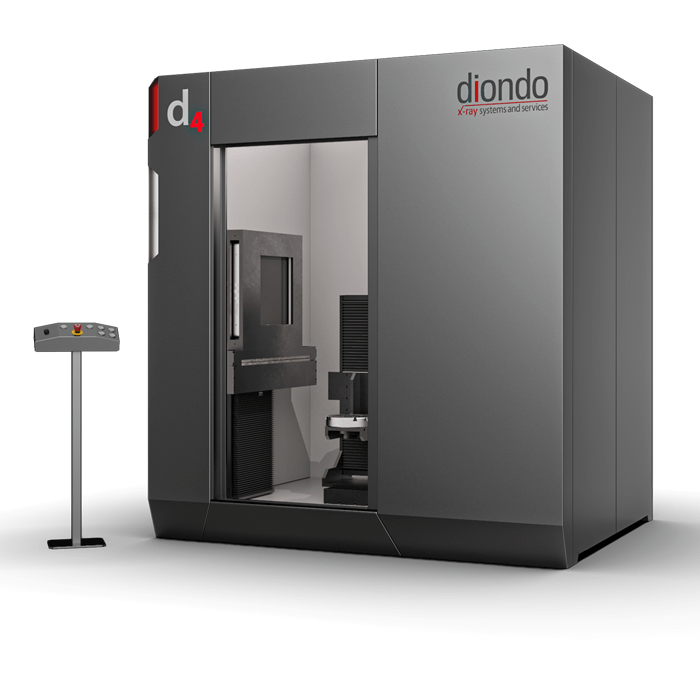

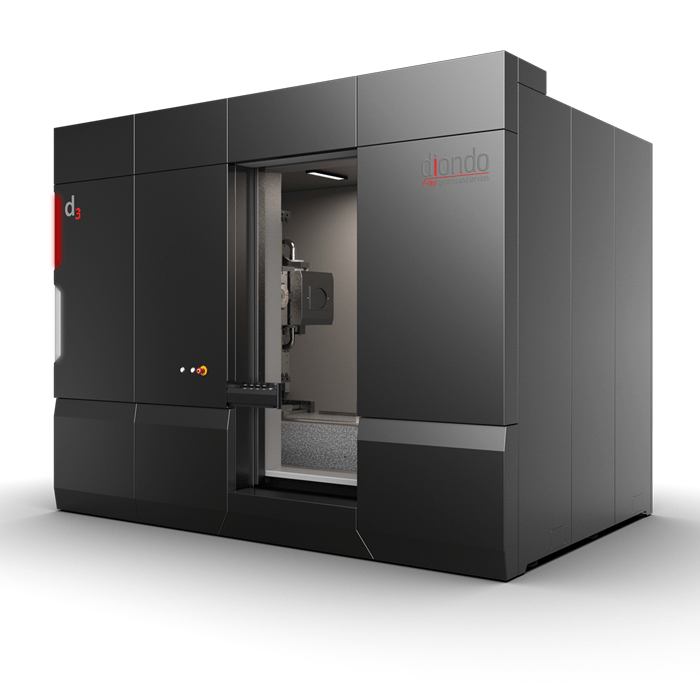

CT Solutions

AXT has a wide range of Computed Tomography solutions from a host of manufacturers that cater for all possible scenarios. We have systems that cater for:

- Size – From small benchtop systems to large industrial systems for examining components in the metre range

- Dynamic (4D) – Need to perform dynamic experiments, we have high temporal resolution systems that ensure you won’t miss important events

- Drill core – We have systems designed specifically to examine drill core samples

- Nanometer resolution – If you are after nanometer resolution but don’t want to go to the synchrotron every time you want to run an experiment, we can help you here as well

In the rare event that we don’t have a system that suits your needs, we can build one for you. We also represent a number of companies that build the key components used in a CT system as well as the associated software.