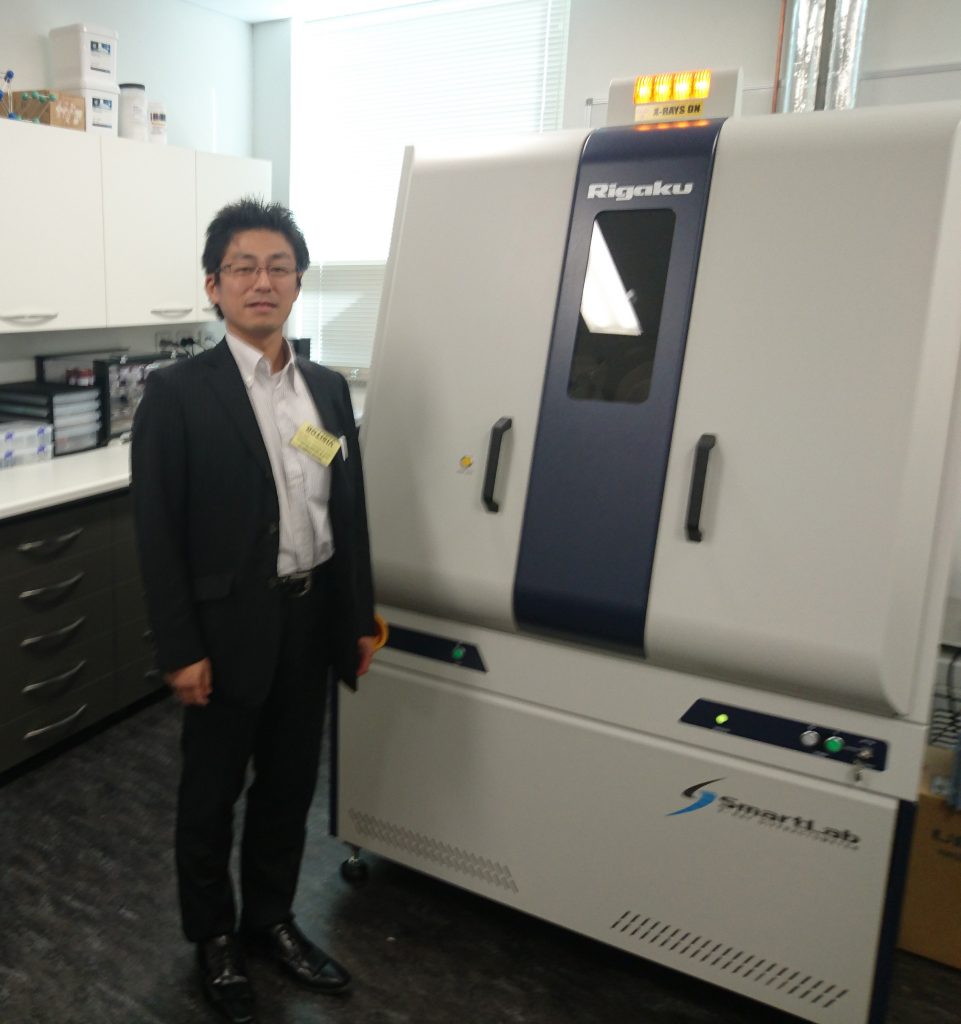

AXT is proud to announce that they have recently commissioned another 9kW Rigaku SmartLab X Ray Diffractometer (XRD). This is the third high-flux XRD to have been installed in Australia and demonstrates that Australia has embraced the technology and advantages that it brings. This system has been installed at CSIRO’s Waite Campus in Adelaide.

The Rigaku SmartLab is arguably one of the world’s most versatile XRD systems. Its range of capabilities can be increased markedly with a host of attachments that can also be added at a later date, including third party attachments. These enable a wider range of measurements to be performed under a variety of configurations and non-ambient conditions. They can all be controlled using Rigaku’s user-friendly guidance software, with Rigaku’s attachment being optically encoded so the system automatically checks to ensure they are correctly installed.

CSIRO have optioned this system with an automatic sample changer which will aid unattended analyses, capillary spinner for analysis of fibres and plate-like crystals as well as transmission stage, SAXS (Small Angle X-ray Scattering) and USAXS (Ultra Small Angle X-Ray Scattering) for characterisation of clays, colloids and other nano-particulates. They also have an Anton Paar CHC+, controlled atmosphere chamber for in-situ monitoring of crystallographic changes at temperatures between 5°C and 350°C in air or other gasses (and up to 400°C under vacuum) and in humid atmospheres between 5% and 95% RH at temperatures from 10°C to 60°C so they can determine how environmental and processing variables will affect materials.

CSIRO’s Mineralogical and Geochemical Characterisation Team Leader Mark Raven uses the 9 kW Rigaku XRD system to assist with his research. Mark said, “our main area of research is characterising geological and mineral samples specialising in characterising clays and clay minerals. The ability to work in SAXS and USAXS modes as well as controlling temperature and humidity is crucial for our work and these were the key features we required.”

Mark and his colleagues’ expertise has been recognised with a win in 2010 and second placing in this year’s Reynold’s Cup quantitative mineralogy round robin. This global competition pits commercial, government, industrial and academic laboratories against one another. They are charged with producing the most accurate quantitative results from supplied mixtures of pure standards that represent realistic sedimentary rock compositions.