Professor Itai Einav at the University of Sydney runs a world-class research facility with unique capabilities specialising in geomechanics and granular physics. This involves the study of the motion of granular materials such as soil and rock and their interaction with obstacles. This area of technology is highly relevant to geotechnical engineering and ensuring the stability of buildings and other engineering structures and preventing disasters like the 1997 Thredbo landslide.

In their laboratories, Prof. Einav and his researchers use experimental, theoretical and computer program models to predict how granular materials behave under various conditions. While problems can appear as simple as flowing sand, the understanding and prediction of such flows and their impact on structures can be very complex requiring the understanding of disciplines such as soil mechanics, fluid mechanics, geophysics and statistical physics. Their work has practical relevance to areas such as silo flow, conveying of grains and powders, hangup delays in block cave mining, mixing and segregation in tumbling mills and rotating drums and segregation of drugs in pharmaceutical powder compactions.

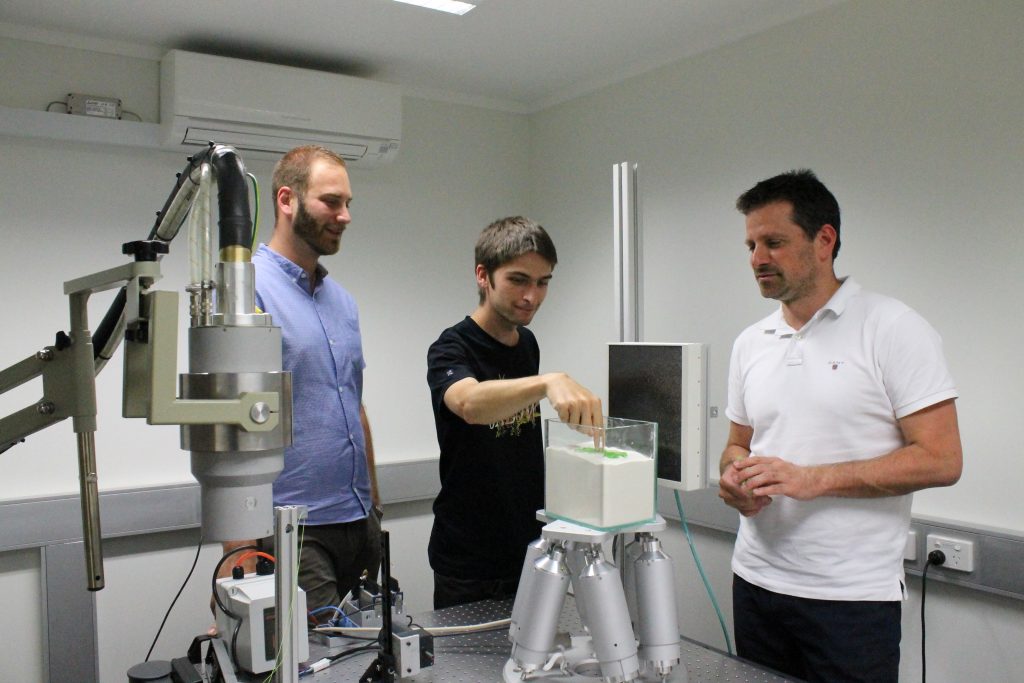

To test their theoretical models, the team have built a range of test rigs to demonstrate different flow and movement scenarios. These set ups allow them to test and model scenarios such as inclines, conveyors, silos etc. They even used a 3D printer to create granules of specific sizes and shapes and monitor the movement and orientation of particles using sophisticated cameras and software.

More recently, they have constructed the world’s first facility for microanalysis of granular flow. While they were able to translate certain methodologies across from previous experiments, they needed to move away from reflected light to give a “deeper” understanding of how materials flow under given conditions.

The logical choice was to use x-rays, which like human x-rays can give you a detailed 2-dimensional picture of what is going on. Although the solution sounds simple, there is a lot more involved. For this reason, Prof. Einav called on the expertise of AXT who have a long history in x-ray equipment and technologies. Together, they designed a custom solution incorporating x-ray source, high-voltage power supply, digital flat panel detector and other ancillary items sourced from AXT’s suppliers.

The hardware supplied by AXT is seamlessly integrated with software and models developed by Prof. Einav’s researchers who can monitor fast flowing dry granular materials. In fact the system works so well, they have decided to look at larger more complex systems. This requires an extension to the existing set up, with an identical system to be configured orthogonally to the original one. This will allow them to capture detailed 3-dimensional images so they can more accurately model real-life systems giving their research more applied applications and relevance.

This new capability will cement Prof. Einav’s team as the world-leaders in their field, giving them the ability to track individual particle motions within larger bodies of flowing particles. Prof. Einav commented, “the addition of this extended capability is fully expected to give us new insights to help us prove or debunk many of the theories that have been postulated relating to materials flow. As a result, we expect to make significant advances in the areas such as turbulence and segregation in granular flows, interactions between particles and flexible intruders in soils and the motion of fluids in porous networks.

They have already generated some significant results in the DynamiX X-ray lab that would not be possible using reflected light. The video below illustrates the insights they can achieve, with more detailed studies soon to be performed when the orthogonal X-ray source and detectors are installed. Keep an eye out for publications from Prof. Einav’s group in the near future!”