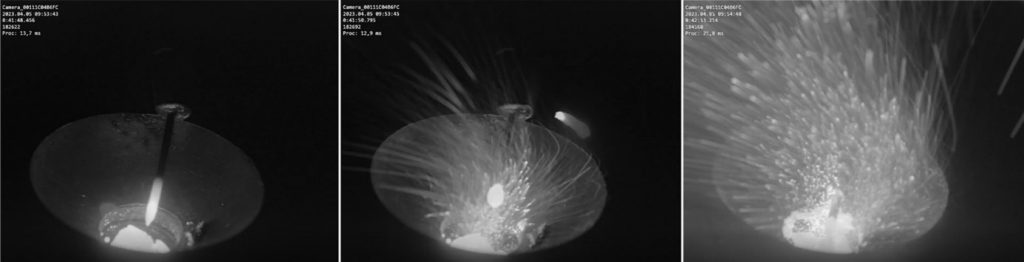

AMAZEMET has announced the development of a new high-energy laser source. This latest innovation, developed under the EU-funded project aims at enabling next-level efficiency and purity for ultrasonic atomisation process.

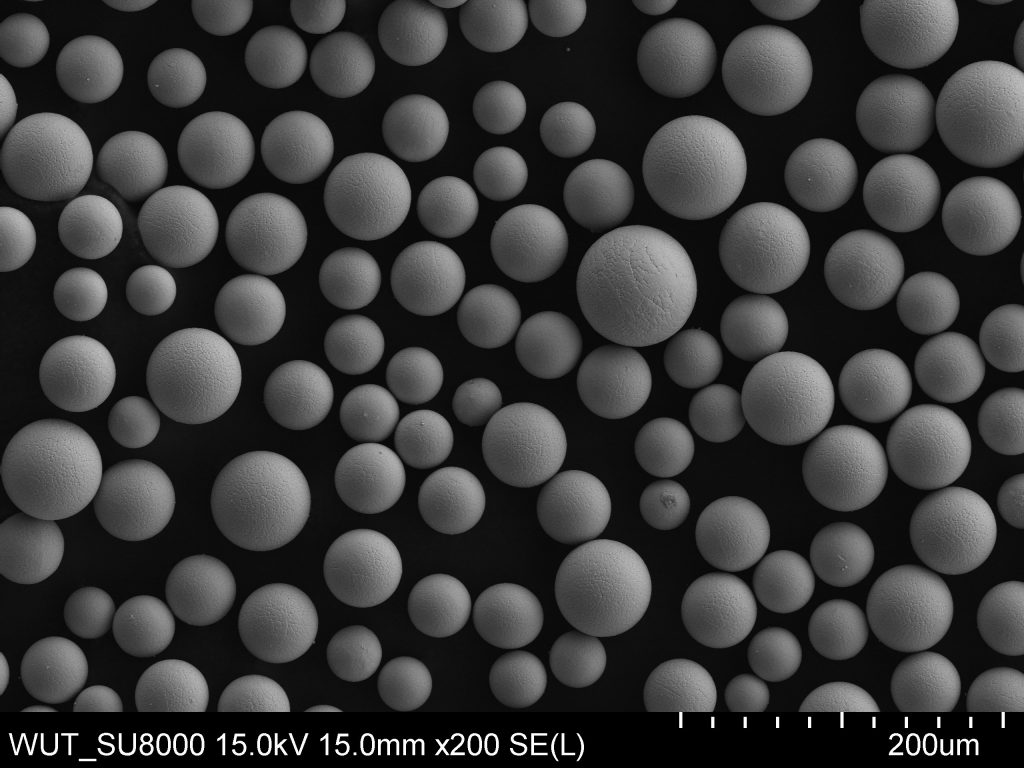

Compared to conventional TIG or plasma-based melting systems, the laser-based energy source provides a highly concentrated and cleaner heat source that ensures more efficient atomisation of high-performance materials. The new melting source will seamlessly integrate into the rePowder atomisation platform, further strengthening AMAZEMET’s position at the forefront of metal powder processing technologies.

Łukasz Żrodowski, inventor and CEO at AMAZEMET, explains: “Laser-beam unlock new capabilities in ultrasonic atomisation. The integration of a precise and highly concentrated heat source allows us to expand the range of materials that can be effectively atomised. By eliminating contamination risks associated with traditional plasma sources, we achieve cleaner, more controlled atomisation with improved powder quality. The ability to fine – tune the energy input of 6kW laser through advanced scanning strategies enables new level of process control for high-performance materials, like C103. We are confident that laser-based ultrasonic atomisation will redefine industry standards in powder manufacturing.”

Key Advantages of the Laser-Based Melting System:

- “One to Melt Them All” – The high-intensity laser enables the atomisation of a broad range of materials, from lightweight aluminum to high-melting-point metals like titanium and niobium.

- “Cleaner and More Precise Melting” – The process eliminates the need for consumable electrodes found in TIG and plasma torches, avoiding tungsten contamination and minimising undesired element evaporation.

- “Automated and Efficient Process” – The laser ensures precise energy input on the sonotrode surface, enabling advanced scanning strategies that optimise material melting, enabling the users to employ expertise from Laser Powder Bed Fusion (L-PBF) and Electron Beam Powder Bed Fusion (EB-PBF).

The integration of the laser-based melting system into the rePOWDER platform is a major step forward in sustainable metal powder production. AMAZEMET continues to push the boundaries of next-generation material processing simultaneously taking active steps to develop and project its IP. Our ultrasonic atomisation platform is already protected by extensive patent portfolio. Further technical details will be announced in the upcoming months of 2025.