On-demand webinar – Watch now

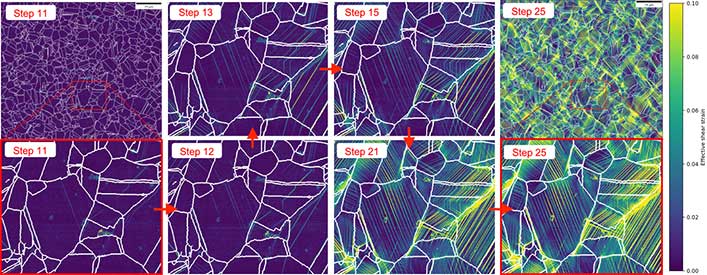

For many technologies, the degradation of materials presents significant and ongoing challenges, limiting the performance, operational life, and sustainability of assets. Materials and devices often fail mechanically and our understanding and capability to predict such failure is still very limited as is understanding of the heterogeneous strain pattern development from the onset of plasticity and linking such patterns to strain hardening and crack initiation.

An important development in recent years has been the advancements in digital image correlation to determine strain patterns at many different length scales. Recent advancements in imaging nano-patterned mechanical test samples in a SEM for high resolution digital image correlation (HRDIC) and combining such data with grain orientation information from EBSD has opened completely new possibilities of understanding the impact of alloy chemistry and microstructures on the deformation patterns that develop during monotonic or cyclic loading.

Recently, the Royce Institute, UK’s National Institute for advanced materials research and Innovation, commissioned the development of a fully integrated in-situ SEM initially focusing on loading, heating and gas injection experiments. I will explain the benefits of this type of fully integrated in situ platform and show examples of plastic deformation of engineering alloys such as titanium and nickel-base superalloys.

I will also introduce the audience to new sophisticated analysis tools that have been developed for the community to obtain high-resolution strain patterns in 100s of grains to quantify level of strain localisation in combination with sophisticated slip system analysis.

Presenter – Prof. Michael Preuss

Department of Materials Science and Engineering, Monash University, Australia

Department of Materials, University of Manchester, UK

Professor Michael Preuss joined Monash University in August 2020 coming from the University of Manchester, UK, where he retains a 20% position. At Manchester he was part of a leadership team delivering the Royce Institute, a national institute for materials innovation.

Michael has been utilising a wide range of lab-based characterisation tools and large-scale research facilities for studying manufacturing and performance of engineering materials for over 20 years. His research focuses particularly on physical and mechanical metallurgy of materials intended for demanding environments such as titanium and zirconium alloys, nickel-base superalloys and certain types of steels widely used by the energy and transport sectors.

He also chairs the scientific advisory committee of the European Spallation Source (Sweden). Michael has published close to 300 peer-reviewed papers and has received several awards including the ASTM Kroll medal for his lifetime achievement in zirconium research.