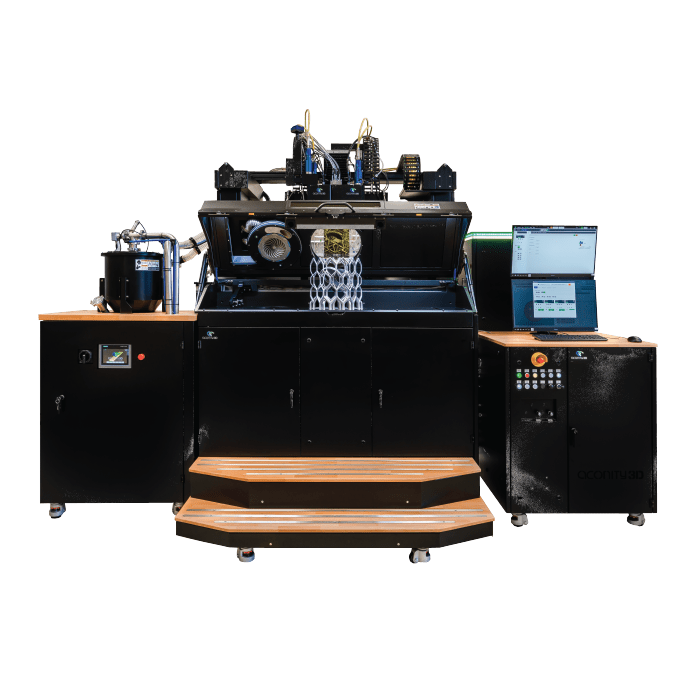

microArch Hybrid Resolution 3D Printers

Additive Manufacturing

High-tech production platform for production of larger industrial parts

Maximum productivity and system flexibility for LPBF fabrication

The AconityTWO is Aconity3D’s latest high-tech production system. Designed for use in the production of larger industrial parts, it features a large-format building platform of Ø 400 mm. To make life easier for operators, the AconityTWO provides an Easy-Access machine cover that allows for quick material changes with simultaneous access to all important technical components.

Common to all Aconity systems, the AconityTWO offers access to all relevant process parameters. Furthermore, the platform’s modular design can be equipped with a preheating device, process monitoring or a modified laser configuration for maximum customer benefit.

To ensure maximum and continuous productivity, the AconityTWO has a fully automated powder refilling system in combination with Aconity’s own sieving station AconitySIEVE. This also enhances operator safety.

The AconityTWO can be configured as a four-laser system for optimal productivity levels. In this configuration, the AconityTWO allows for a full-overlap of all laser sources onto the complete build area of 400 mm at variable laser spot sizes of 80 – 500 µm. In addition, lasers can be configured for master-slave operation for targeted preheating and postheating of local component areas during the build. This is controlled by Aconity’s in-house developed 3D scan head technology.

Run time – 2:34min

Take a quick tour of the AconityTWO and see what it is capable of. This sytem featured the Multi-scan-head which enables true scalability beyond the size of the platform as well as controlling laser spot size for increased productivity.