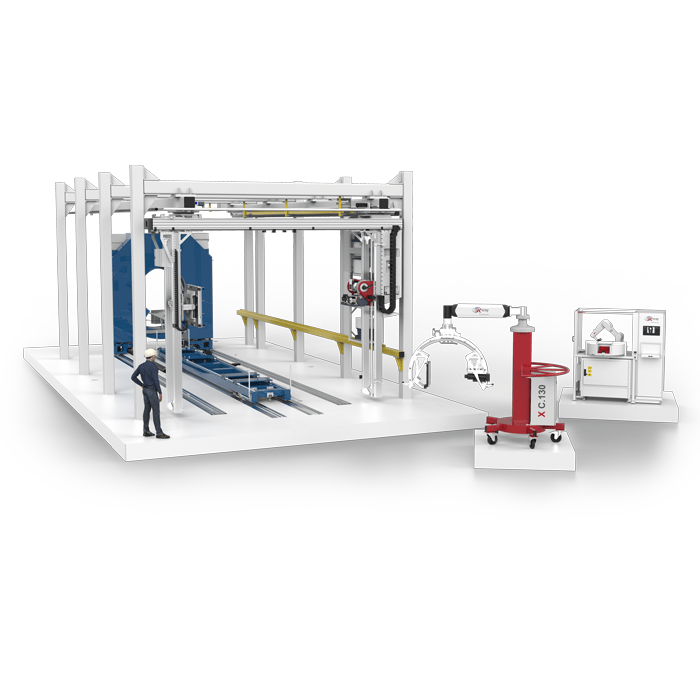

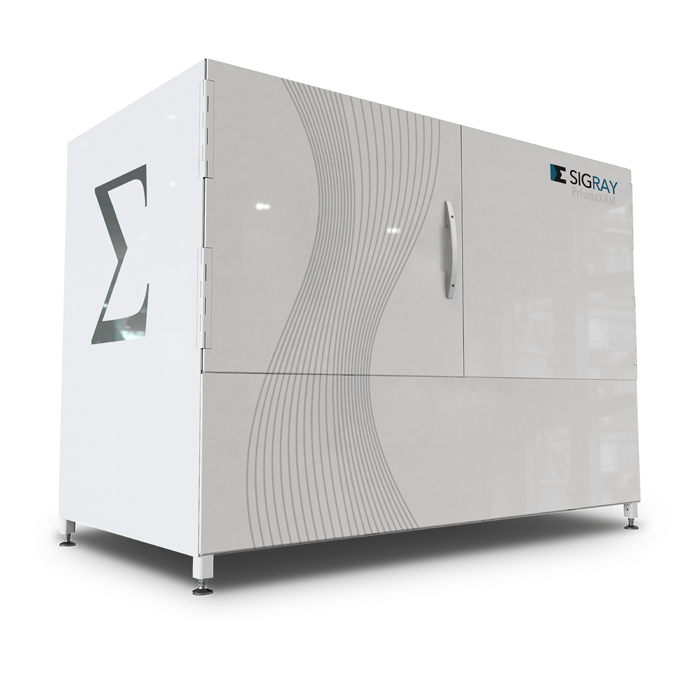

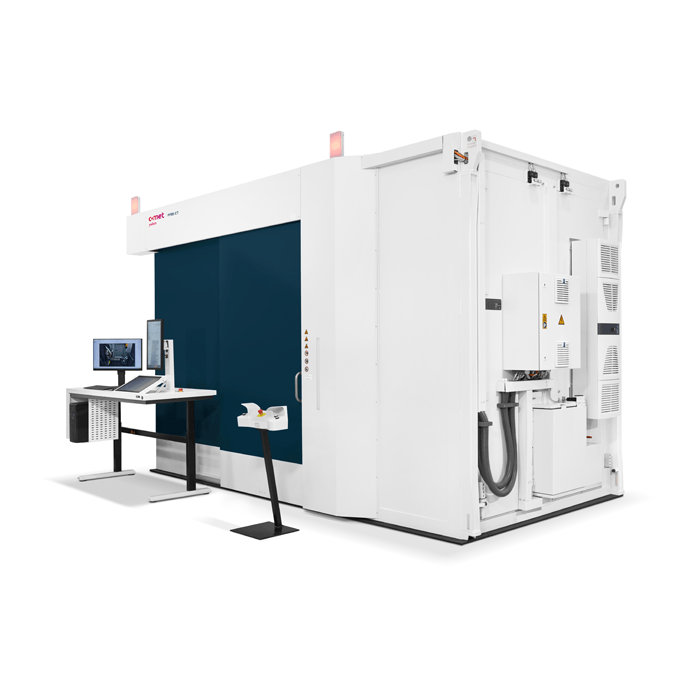

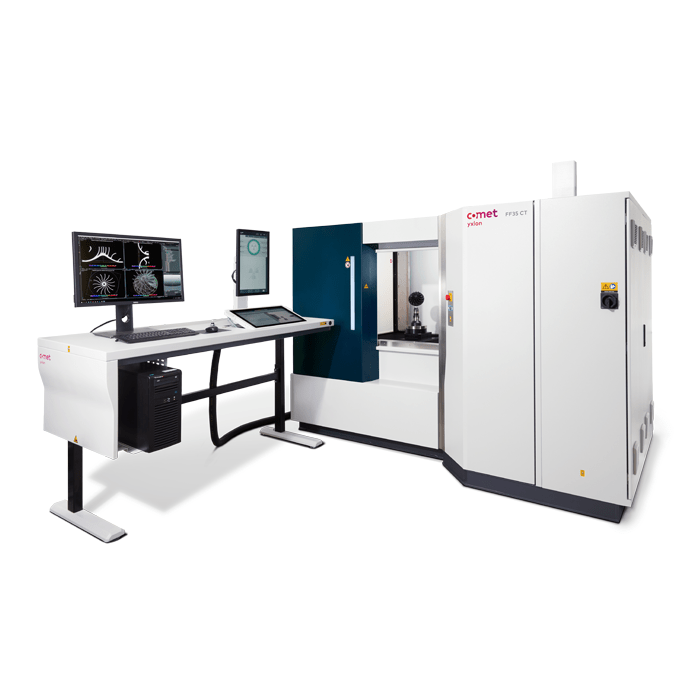

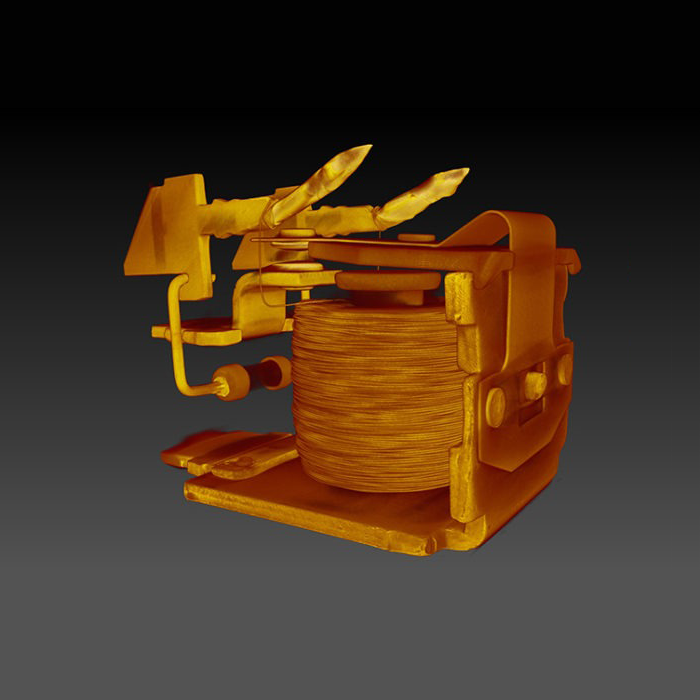

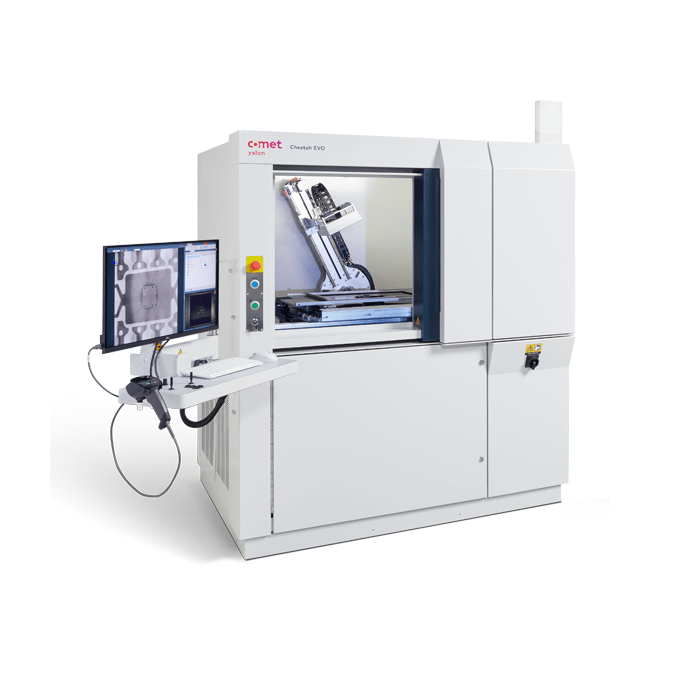

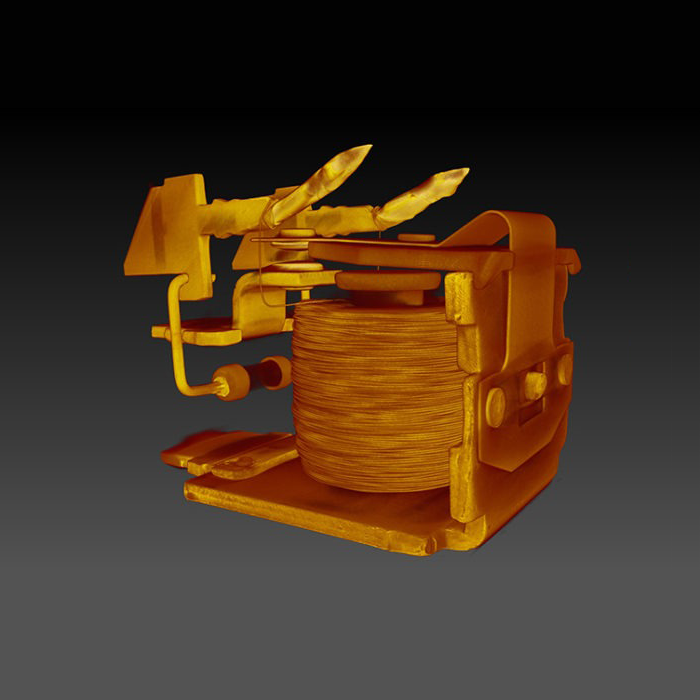

Cheetah EVO 2D/3D Inspection System for Small Components

A CT system for demanding electronic applications without compromise

The Comet Yxlon Cheetah EVO series was designed to provide the “best-in-class” inspection solution for SMT, semiconductor, and laboratory assembly applications

-

Key Features

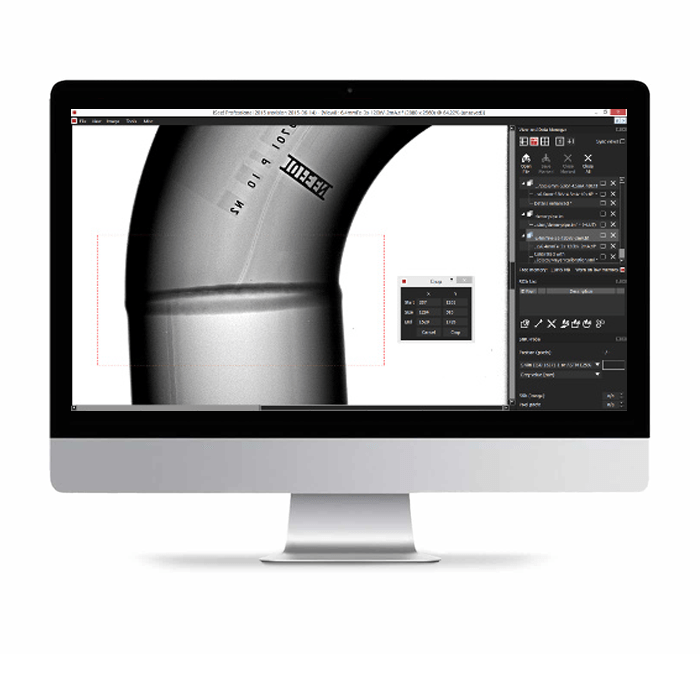

- High resolution images - Makes faults easy to identify

- Ready for Industry 4.0 - The Cheetah EVO includes several new and improved features that make the system ready for the paradigm shift to a smart factory

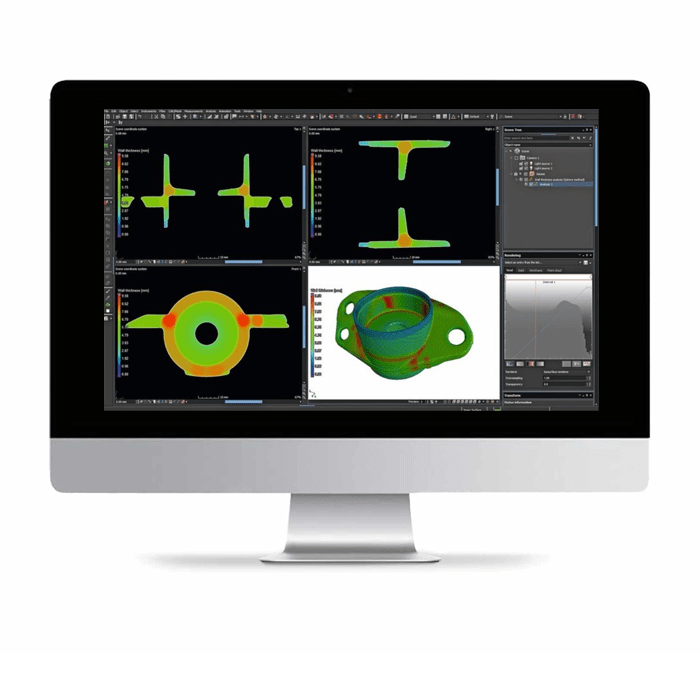

- YXLON ProLoop - Yield enhancement software solution, with real time reporting

- Intuitive workflow - Makes it simple to program automated procedures

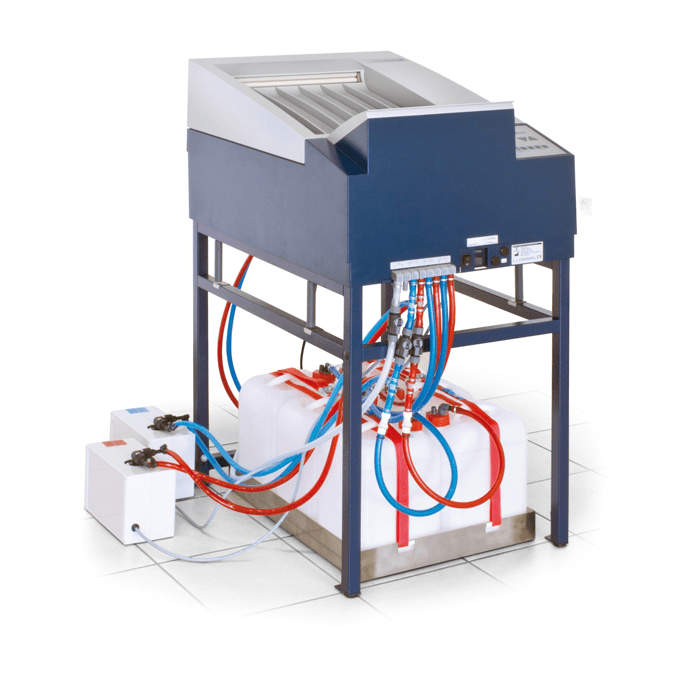

- Flexible - 3 models designed to suit most electronic and similar applications

The Comet Yxlon Cheetah EVO series was designed to provide the “best-in-class” inspection solution for SMT, semiconductor, and laboratory assembly applications through to electronic components (including batteries) to medical materials. With optimised software and hardware, these systems produce higher quality and more consistent results than other electronics inspection systems currently on the market.

The Comet Yxlon Cheetah EVO range of X-ray inspection solutions provide sheer visual brilliance. The Cheetah EVO range provides users with a brilliant image in the shortest time, in each of its market sectors. This because the Cheetah EVO systems harness the combined power of several Comet Yxlon innovations

- FeinFocus X-ray tube technology

- High-power target technology

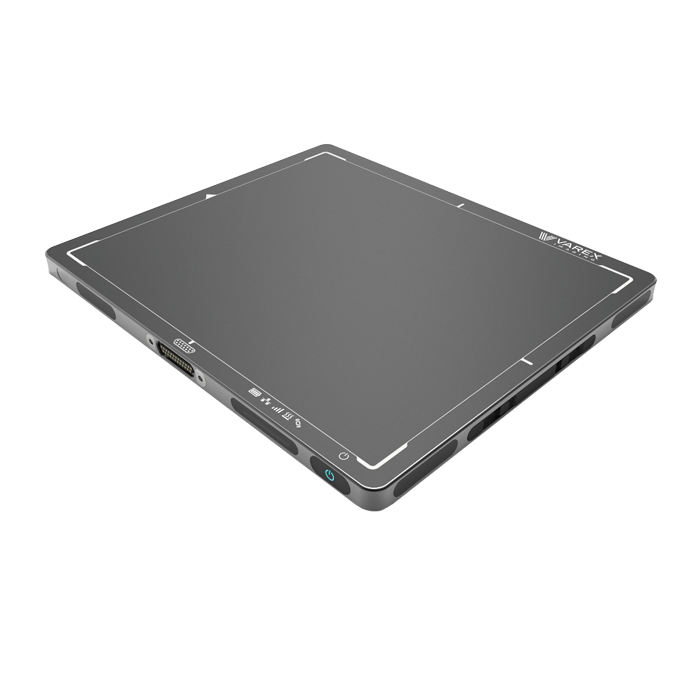

- A finely calibrated, long-life flat-panel detector and a state of the art

manipulation system.

- All

- Additive Manufacturing

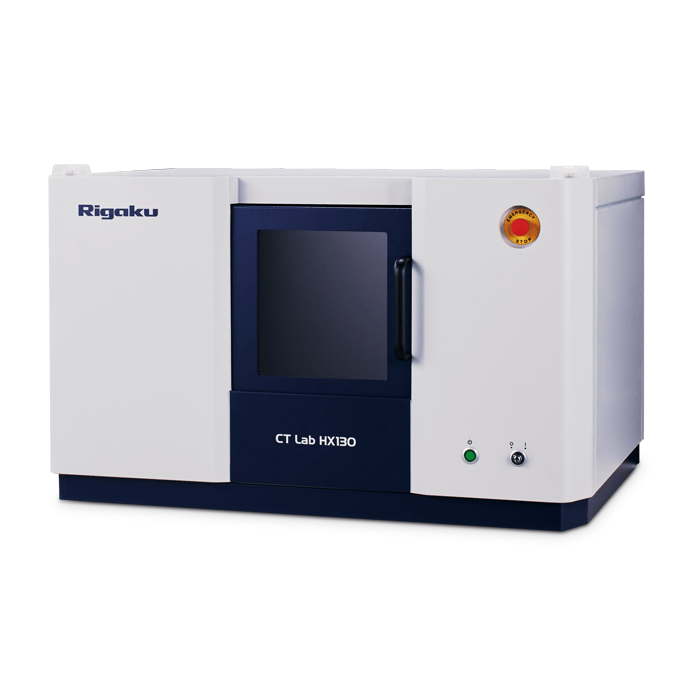

- Computed Tomography

- Computed Tomography - Life Sci

- Fluoroscopy

- In situ

- Radiography

- X-ray Imaging

- X-ray Microscopy