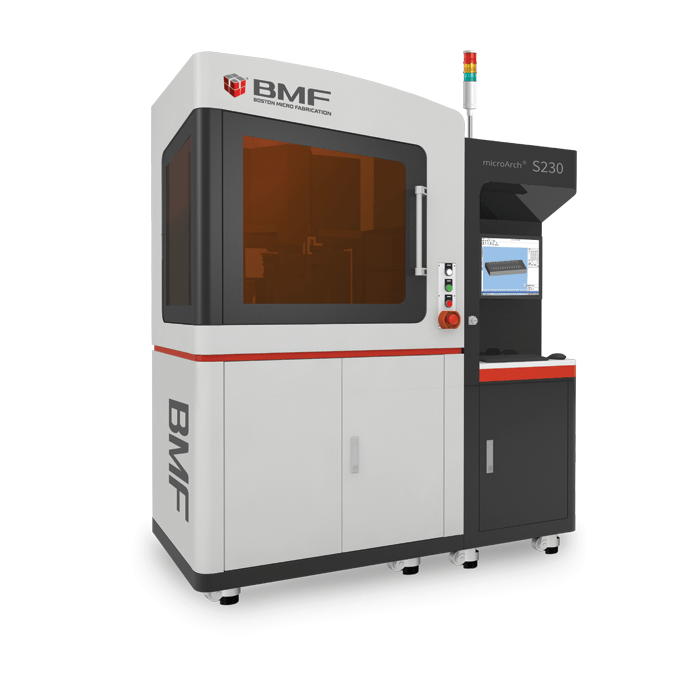

microArch Hybrid Resolution 3D Printers

Additive Manufacturing

World leader in micro-precision 3D printers utilising Projection Micro Stereolithography (PµSL) technology

Ultra-high resolution, accuracy and precision

Micro 3D printing is ideally suited to a wide range of 3D printing applications catering to a broad variety of industries. Combining ultra-high resolution, accuracy and precision, BMF micro precision 3D printers can produce more intricate, exact and replicable parts and are perfect for rapid prototyping applications.

Provided below are some of the many examples that these systems are suited to.

| Medical | Electronics | Microfluidics | Micro-mechanical devices | Education/research |

|---|---|---|---|---|

|

|

|

|

|

Run time – 1:48 min

Tim explains how the precision and accuracy of BMF 3D printers have helped them to produce rapid prototypes as well as final products for medical applications. BMF helped them to bring their prototypes to reality in a very short timeframe and he described their precision as “superior for miniature applications”. Furthermore, they are looking to using BMF’s technology and materials for projects in the future.

Run time – 3:32 min

The microArch® S240 offers higher print speeds and larger print volumes using strong, more durable materials for the needs of industrial production using their Projection Micro Stereolithography (PµSL) technology.

Most significantly, the microArch® S240 incorporates an advanced roller over the top of the membrane that results in build speeds up to 10x faster than current platforms and it has the ability to handle higher viscosity materials. These make it an extremely cost-effective and efficient solution for short-runs of high-precision industrial parts.

Examples of medical applications include:

Example applications of high-precision 3D printed parts or electronics include:

Examples of the BMF 3D printers for R&D include:

Here are some other examples of what can be produced using BMF’s high-precision 3D printers: