Mini Transfer Module for Sensitive SEM Samples

SEM

Give your microscope a hand

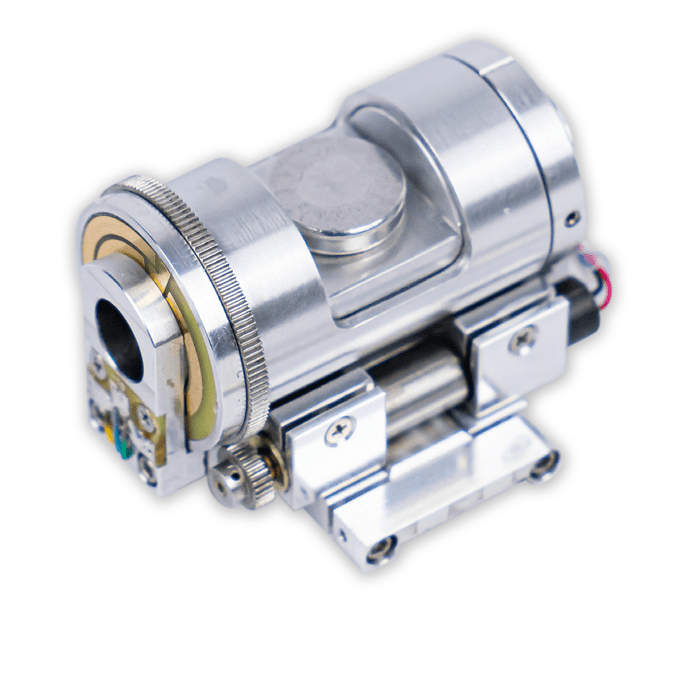

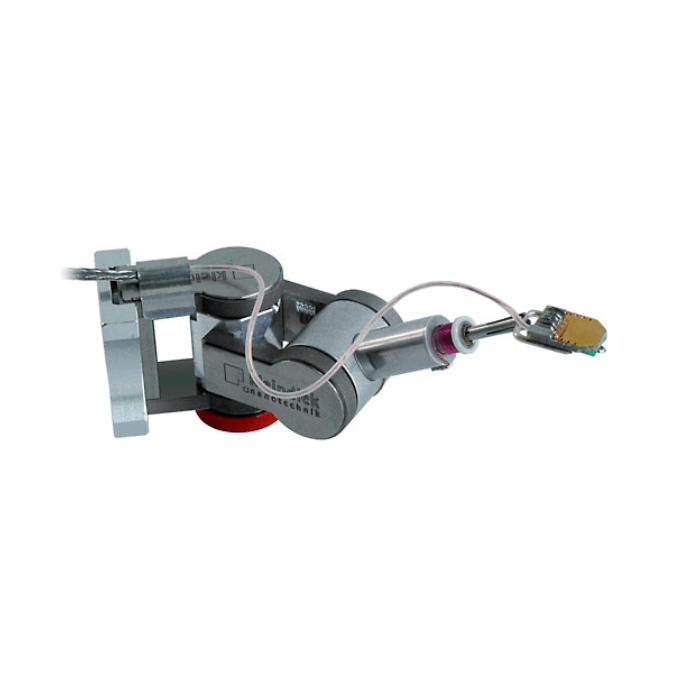

Adding capabilities from in-situ lift-out, electrical probing (FA)and nano-manipulation, the encoded MM3E micro-manipulator brings new functionality to your SEM or FIB/SEM instrument.

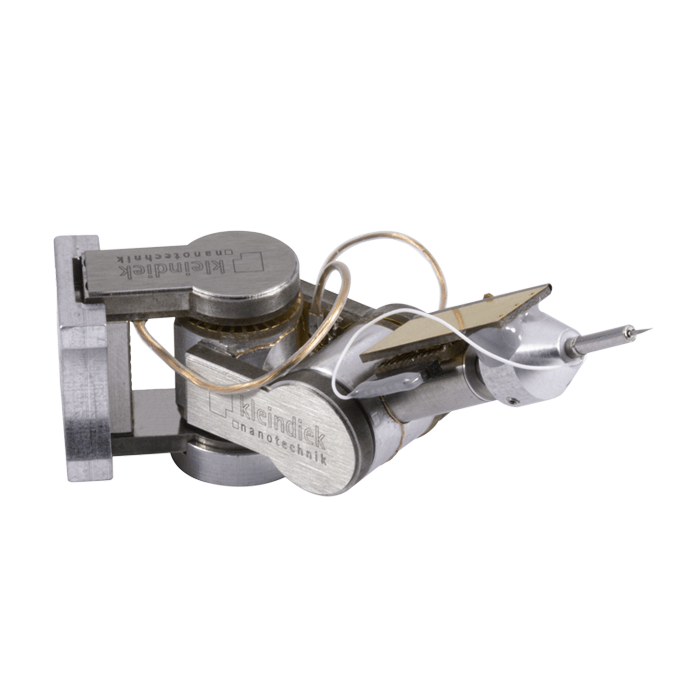

The MGS2-EM is a microgripper plug-in for the MM3E micromanipulator. It enhances your system by providing a high-resolution gripping solution for transport and assembly of micro-sized objects. The gripper arms are tungsten probe tips and are piezo-controlled, allowing a step size of 20 nm. The gripping force can be derived from the NanoControl’s display. Custom-shaped gripper tips are available on request.

To view brochure click on the link below.

https://www.axt.com.au/wp-content/uploads/2019/06/Kleindiek-Microgripper-AXT.pdf

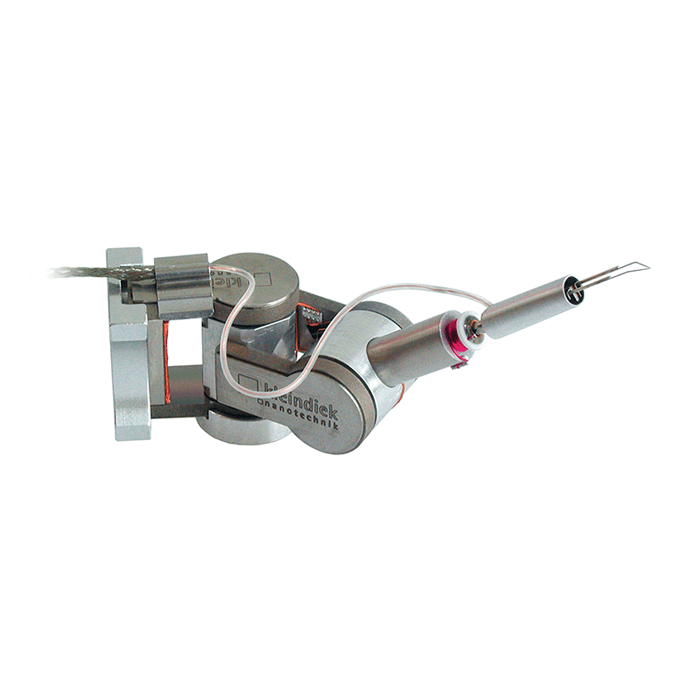

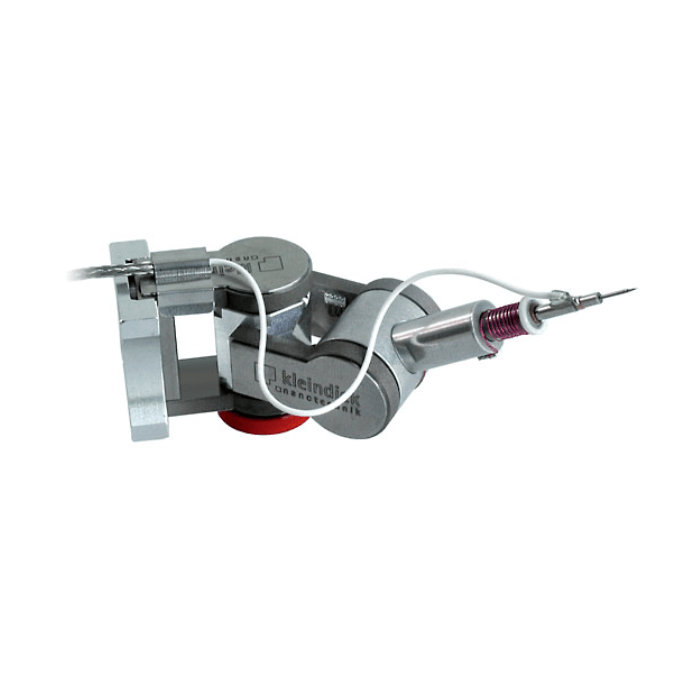

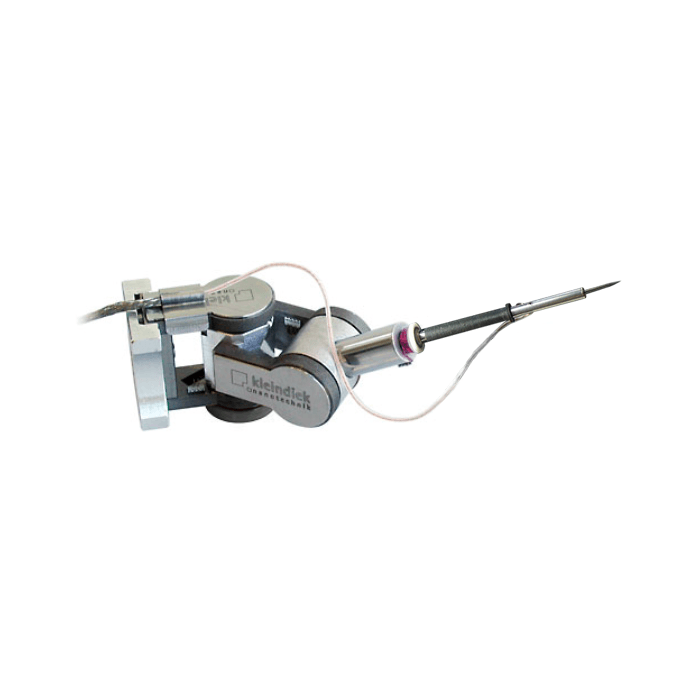

The ROTIP-EM is a rotational axis plug-in for the MM3E micromanipulator. It enhances your system by providing a fourth degree of freedom that is required for numerous SEM and FIB applications. Standard tungsten probe tips can be inserted into the front of the axis and rotated with a resolution of 0.1° per step, allowing applications such as advanced TEM prep, tomography and STEM to be performed with ease. In addition the MGS2-EM microgripper can be combined with the rotational tip to allow gripped objects to be rotated.

To view brochure click on the link below.

https://www.axt.com.au/wp-content/uploads/2019/06/Kleindiek-RoTip-AXT.pdf

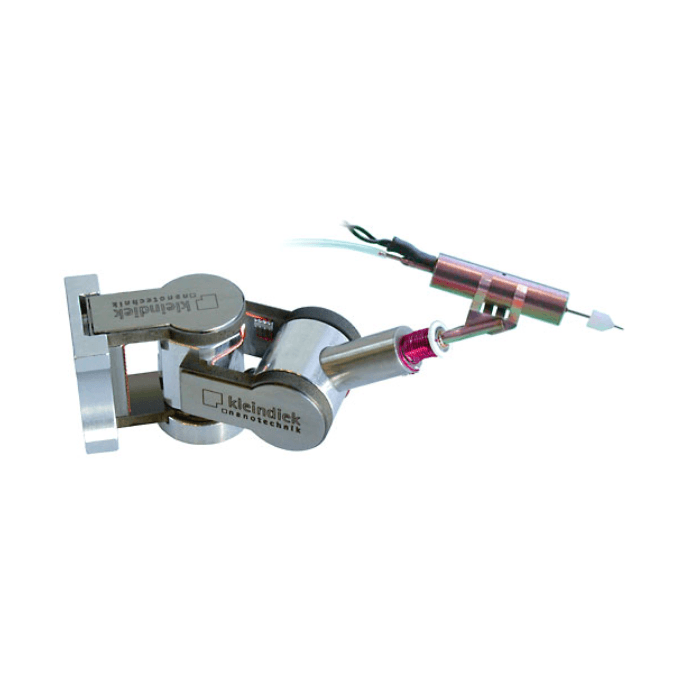

The LCMK-EM is a low-resistance, low-noise probe tip holder for the MM3E micromanipulator. It enhances your system’s nanoprobing capability by allowing low-capacity, low-current measurements on conductive samples. Standard tungsten probe tips can be inserted into the front of the LCMK-EM tip holder. Triax cabling and feedthroughs carry signals through to a connector which fits all conventional parameter analyzers.

To view brochure click on the link below.

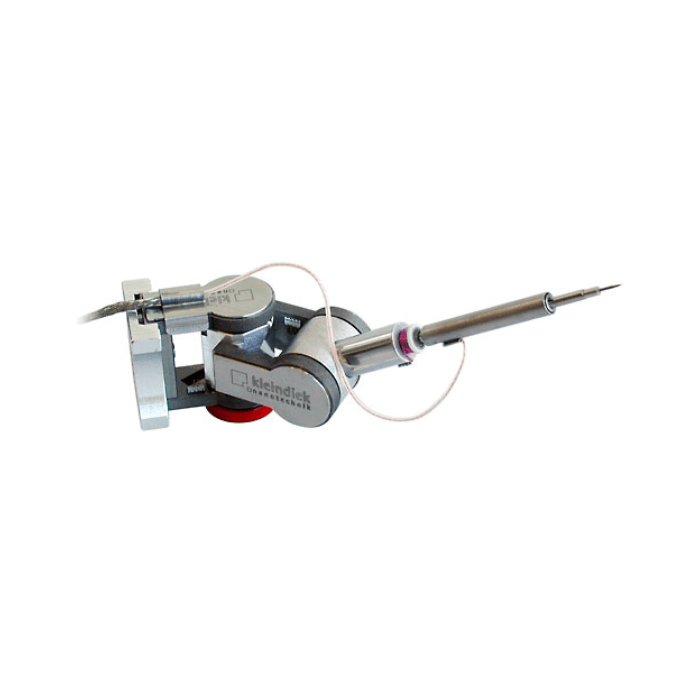

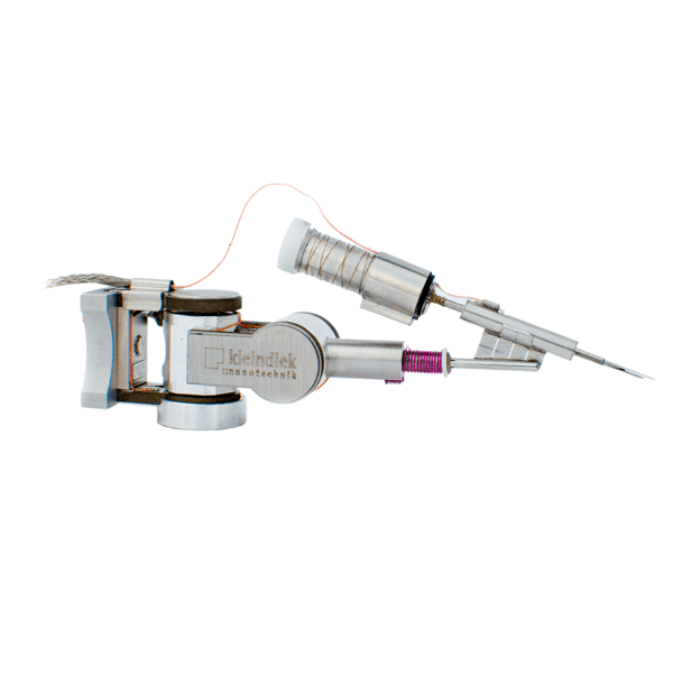

The MSU is a plug-in system for the MM3E that adds a miniturized soldering iron to your experimental setup. The plug-in provides a solution for heating a small tip. The unit has an integrated heating and sensing system in order to maintain the temperature set using the included Temperature Control System. The Micro Soldering Unit can be fitted with custom tips that have a shaft diameter of 0.5 mm.

To view brochure click on the link below.

https://www.axt.com.au/wp-content/uploads/2019/06/Kleindiek-MSU-EM-microsoldering-AXT.pdf

The MIS-EM is a micro-valve plug-in system for the MM3E micromanipulator. It enhances your system by allowing you to microinject various liquids onto your samples in low-vacuum SEM. The unique combination of precision manipulation and controlled microinjection has attracted a lot of interest in the MIS-EM since its launch.

To view brochure click on the link below.

https://www.axt.com.au/wp-content/uploads/2019/06/Kleindiek-Microinjector-AXT.pdf

The GIS-EM is a gas injection plug-in system for the MM3E micromanipulator. It enhances your system by allowing you to inject various gases into the SEM chamber. The unique combination of precision manipulation allows safe and controlled injection of media from solid or liquid precursors. The precursors are placed inside the temperature controlled reservoir where they evaporate when heated. It is also possible to inject gaseous precursors such as Argon, e.g. for charge compensation. Minute amounts of gas are released in precise doses using the proportional valve which is in turn actuated by a Nanomotor®.

To view brochure click on the link below.

https://www.axt.com.au/wp-content/uploads/2019/06/Kleindiek-Gas-Injection-AXT.pdf

The FMS-EM is a compact force readout tool for the MM3E micromanipulator. It enhances your system by allowing you to perform force measurements and nanoindentation. Smallest outer dimensions are possible by means of a force readout system that requires no laser. Force feedback on the display of the controller is coupled with a loudspeaker to enable you to intuitively characterize materials and micromechanical structures by their resonance frequencies. Sharp silicon tips allow nanoindentation in a wide variety of materials. The latest version of the system offers a complete force measurement solution including software for data acquisition, visualisation and export. The controller offers easy operation, measurement calibration at the touch of a button and a USB interface. The novel software features a calibration wizard for the Force Measurement Tips and is capable of recording force-time curves.

To view brochure click on the link below.

https://www.axt.com.au/wp-content/uploads/2019/06/Kleindiek-Force-Measurement-AXT.pdf