BIO ONE

BioprintingExtrustion Bioprinters

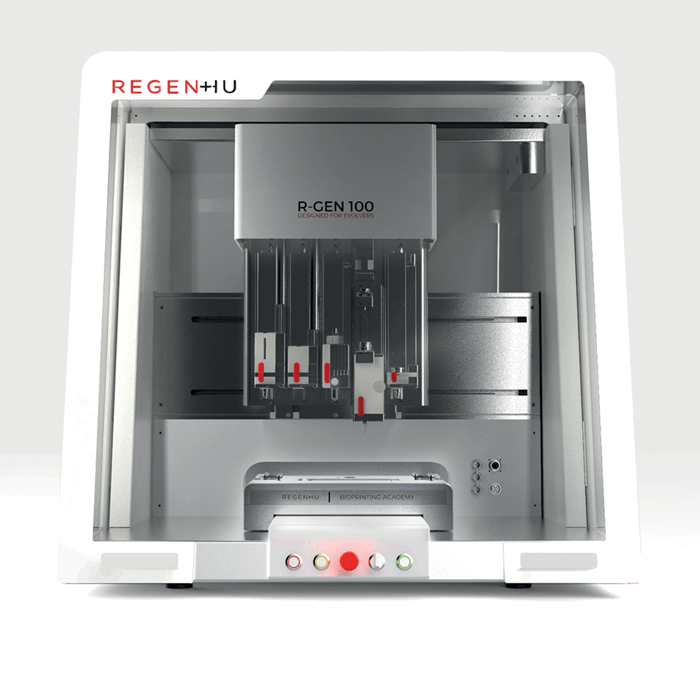

The tabletop 3D bioprinter bringing the future of medicine closer

Each R-GEN bioprinter is personally configured to specifically meet your needs of your bespoke research goals.

Combine jetting, contact dispensing and electrowriting technologies with a full range of auxiliary process options to build simple or complex constructs.

REGENHU’s scientific advisors are available to guide you to your optimal instrument.

The R GEN multimodal bioprinter allows you to tailor your system to your specific requirements combining multiple printing technologies in a single process to mimic native tissue architecture, composition and complexity.

Pneumatic extrusion enables versatile processing of a wide range of different bioinks.

The light-curing kit enables for a fast, in-process crosslinking of photocurable materials while minimising the dose provided to cells.

The easy-to-use, intuitive SHAPER software and accurate optical calibration systems allow the process to be easily and automatically repeated in multiple wellplates for high-throughput screening.

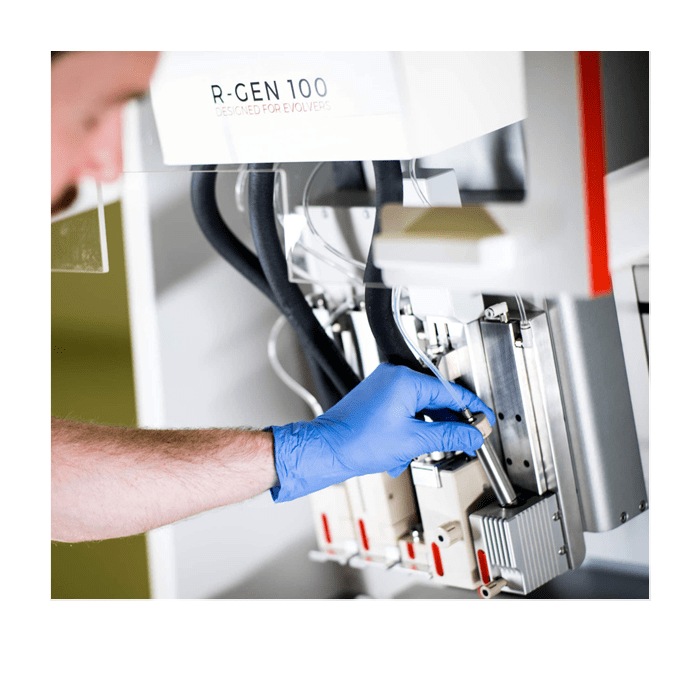

Multimaterial extruder for advanced formulations dispensing.

Ideal for heterogeneous tissue engineering, drug discovery, biomaterial processing and core-shell printing

Independent temperature management of each material cartridge and extrusion nozzle temperature and workzone ensures you maintain optimal print conditions.

All R-GEN instruments are built with the ability to be easily upgraded with electro-spinning and writing technology allowing the creation of micro- and nano-fibers.

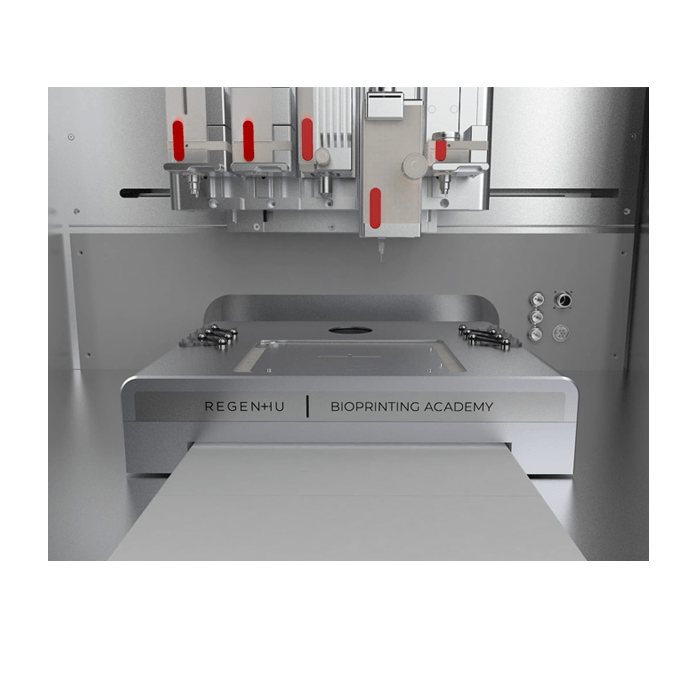

The instrument modularity gives you the possibility to easily and quickly change your instrument base plate according to your needs.

Select amongst 4 different workzones to manage temperature in the physiological range or above, to generate micro- and nano-fibers, or to simply print in specific labware.

Adjust and refine print parameters any time during the print process.

Visualize the protocol sequence and action status with the progress tracker.

Run trial print protocols using rough print parameters, close-up observation and real-time parameter adjustments to quickly identify optimum protocol conditions.