microArch Hybrid Resolution 3D Printers

Additive Manufacturing

Providing additive manufacturing researchers with the freedom to economically produce customised metal powders in small batches

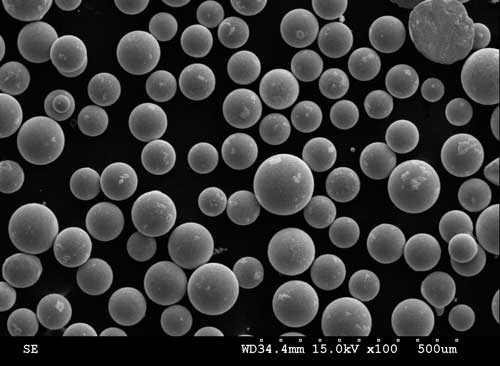

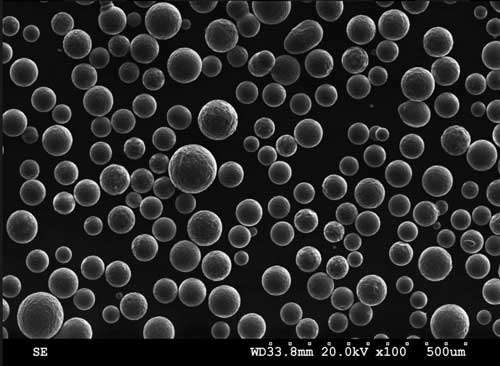

Ultrasonic atomisation provides an alternative to conventional gas atomisation for powder production for additive manufacturing. It is ideally suited to production of small batches, offering users the freedom to produce powders of virtually any composition, using any feedstock you can obtain to produce spherical powders of narrow particle sizings with excellent flow characteristics. rePOWDER is the perfect solution for those who only need to produce small volumes of powder and those wishing to create and refine powder compositions.

Compared to gas atomisation, ultrasonic atomisation is better suited to production of small quantities of metal powders, offering a more economical alternative, including resource and time efficiencies. Its’ modular design enables the use of different heating modules depending on the melting point of the feedstock, with the ability to produce metal powders from grams to kilograms.

It also has the versatility to accept almost any feedstock. Amazemet have developed systems to deal with wire and powder, enabling you to convert these into spherical powders of your desired particle size ideal for 3D printing or thermal spray.

Feed metal is melted using arc/plasma (up to 3500°C) or induction (up to 1300°C) depending on its melting temperature. The molten metal is dropped onto a vibrating surface causing ejection of tiny metal droplets. These droplets are solidified in an inert environment, resulting in formation of the metal powder.

The size of the metal droplets and hence metal powders can be controlled by the ultrasonic vibration frequency, with higher frequencies yielding smaller powders.

Click here for more details about the ultrasonic atomisation process.

Run time – 1:20 min

Production of Ti6Al4V titanium powder via ultrasonic atomisation using the Amazemet rePOWDER system. Feedstock is a piece of scrap Ti6Al4V demonstrating the system’s flexibility.

Run time – 1:18 min

Production of bronze powders suited to additive manufacturing using induction melting and ultrasonic atomisation.

Run time – 2:40 min

Showing how 1kg of silver can be atomised in just 10 min using the rePOWDER ultrasonic atomiser and induction furnace, suitable for low melting point metals.

Run time – 58sec

This schematiic representation demonstrates how the rePowder system can convert existing powder feedstocks (including used powder) into highly spherical powder, suited to 3D printing or thermal spraying.