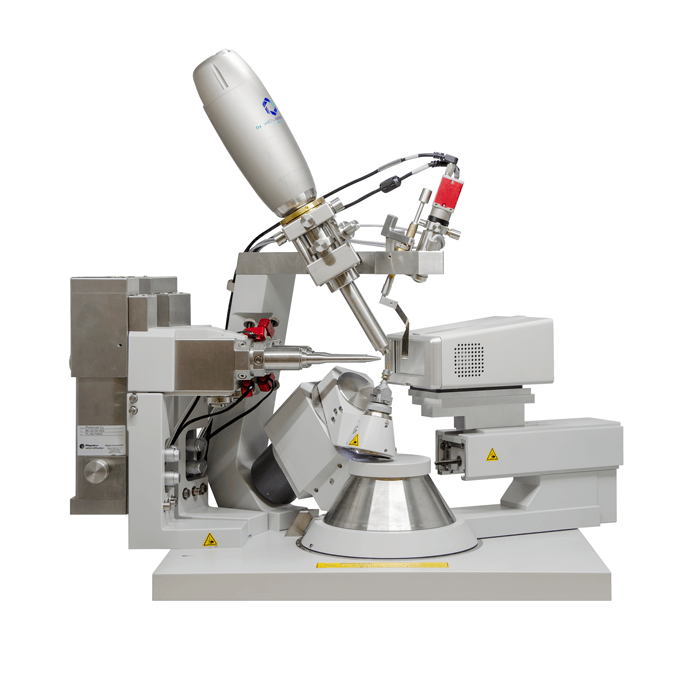

XRTmicron

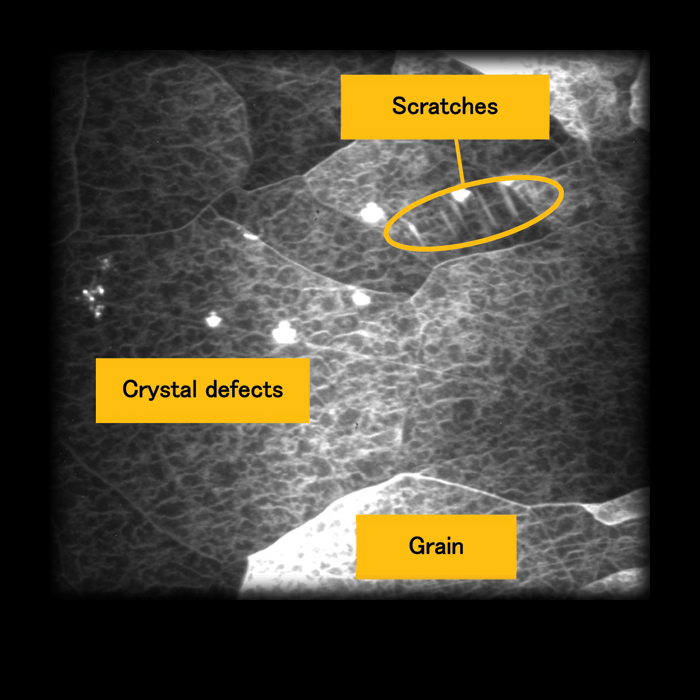

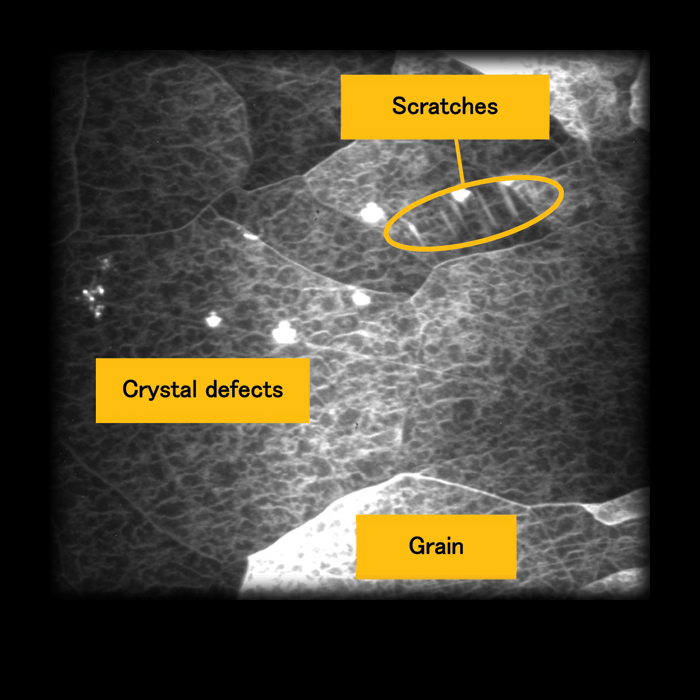

X-ray topography imaging system, for the non-destructive evaluation of single-crystalline materials.

Fully Automated Topography Engineered for Performance

-

Key Features

- High-brilliance dual-wavelength X-ray source: MicroMax-007 DW

- High resolution CCD camera: XTOP (5.4 μm pixels

- Ultra-high resolution CCD camera: HR-XTOP (2.4 μm pixels)

- Horizontal sample mount for minimum artificial strain to wafers

- Automatic wafer curvature correction for best dislocation image quality

- Automated system operation including X-ray anode switch, detector switch, optics switch and alignment, sample alignment, and image collection

- Automated dislocation analysis

- 3, 4, 6, 8, 12 inch wafers supported

- Wafer loader compatible

Rigaku XRTmicron is a fast, high-resolution laboratory X-ray topography system for non-destructive dislocation imaging. Various types of dislocations and non-uniformity within single crystal wafers (such as Si, SiC, GaN, Ge, GaAs, quartz, sapphire, rutile, calcium fluoride etc.) can be imaged across wafers up to 300 mm in diameter. X-ray topography is a widely used dislocation analysis technique for both research and development and process control by various single crystal, wafer and device manufacturers.

Crystal defect analysis of a single crystal substrate by X-ray reflection topography

- All

- DNA/RNA

- Electron Diffraction

- Micro XRD

- Molecular Biology

- Powder

- Protein

- Protein Crystallography

- SAXS/WAXS

- Small Molecule

- Thin Film

- XRD & Diffraction