Regenerative medicine and tissue engineering have seen unprecedented growth in the past decade, driving the field of artificial tissue models towards a revolution in future medicine. Major progress has been achieved through the development of innovative biomanufacturing strategies to pattern and assemble cells and extracellular matrix (ECM) in three dimensions (3D) to create functional tissue constructs.

Bioprinting has emerged as a promising 3D biomanufacturing technology, enabling precise control over the spatial and temporal distribution of cells and ECM. This technology can be used to engineer artificial tissues and organs by producing scaffolds with controlled spatial heterogeneity of physical properties, cellular composition, and ECM organization—an innovative approach increasingly utilised in biomedicine.

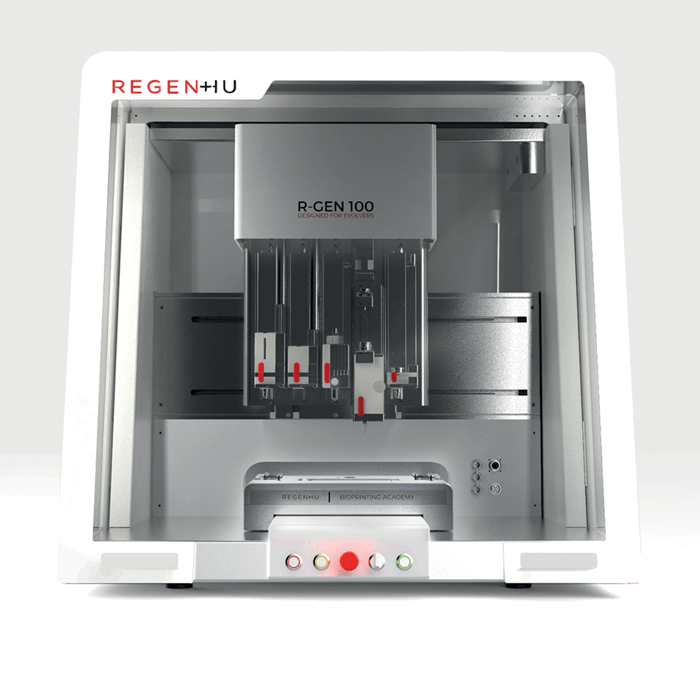

The REGENHU Bioprinting Platform – A combination of innovation, performance and ergonomy

It covers the entire bioprinting process—from definition and design to execution and evaluation of the print constructs. Its flexibility, comprehensive bioprinting capabilities, and innovative ergonomy offer unique advantages. The bioprinting instruments and software facilitate the user journey across a gamut of applications for both research and industry.

Exceptional Instruments, Control Software and Planning Software in one platform

The R-GEN 100 tabletop bioprinter and the R-GEN 2003D bioprinting station are designed for high accuracy and repeatable printing of cells, bioactives, and biocompatible materials. This helps in the development of tissue models and the replication of human tissues. REGENHU combines up to five print tools with independent thermal control, and different print technologies or multiples of the same print tool can be installed on one instrument. It offers the user great flexibility and versatility while ensuring the reproducibility of the constructs.

Plan, Define, Design, Print, Monitor, Evaluate, Manage, and Share

With its end-to-end configurability that is personalised to a user’s needs, the REGENHU Bioprinting Platform provides a comprehensive, all-in-one solution to manage and realize all bioprinting/biofabrication projects of today and tomorrow—from design and planning of the biofabrication process through the execution of the constructs to real-time adjustments, full process interaction and visualization of the parameters to get the best results and to save time during protocol development.

A multiple-award platform

The R-GEN 100 is now being recognized by its peers by winning the Red Dot and the iF awards—two of the world’s most renowned design and innovation competitions. The former focuses on innovation values, logic, and ergonomics while the latter emphasizes aesthetics and perception. This solid recognition celebrates REGENHU’s commitment to designing innovative, high usability, and ergonomic instruments that improve people’s lives.

“We couldn’t be happier to celebrate this milestone that is a paramount achievement. It proves our perpetual ability to create a 3D bioprinting platform that combines usability and function, but most importantly, improves our daily lives through its contribution to evolve medicine,” said Denis Crottet, Chief Business Officer of REGENHU.

Red Dot Design Award

“The winners of the Red Dot Award created excellent products worthy of winning an award. The products won over the jury not only through their aesthetic, but also for their incomparable functionality. With their designs, the award winners are setting new standards in their industries. I wish to congratulate them most sincerely on their success,” said Dr. Peter Zec, Founder and CEO of Red Dot.

The Red Dot jury celebrated the R-GEN100’s functionality, design quality, and ergonomics. The clean lines and distinctive colour scheme highlight the 3D bioprinter’s inner reliability and quality.

“We are extremely proud to announce that we have won two major recognitions worldwide for our outstanding innovation and product design quality, marking an important milestone in the biotech industry. This is just a step to demonstrate our commitment to delivering high quality. REGENHU is helping its customers with their bioresearch goals today and their biofabrication and production goals of tomorrow. We have the knowledge, the skills, and the passion to build these instruments for their future. We are revolutionizing medicine today,” said Simon MacKenzie, CEO of REGENHU.

iF Design Award

After different evaluation meetings, R-GEN 100 reached the Final Jury comprising three jurors who assessed the entry against five criteria. The R-GEN 100 has been selected for its impressive form, outstanding usability and ergonomics, and the remarkable impact it has on people’s lives.

“It definitely shows that strategic design process enables innovation performance ergonomy. This is what REGENHU has been doing. We are proud that the R-GEN 100 has been recognized by the design community,” said Denis Crottet, Chief Business Officer of REGENHU.

Ergonomic product design is by no means an easy task. The technical and organizational conditions that influence human interaction with the instrument must be taken into account to prevent any risk, disability, or impairment when using them. Material selection, external shape, and incorporating a simplified internal structure is an excellent example of how minimalist design can be combined with ergonomic features.

The R-GEN 100 and the R-GEN 200 consolidate 14 years of bioprinting technology and development based on incorporating industry knowledge, integrating user feedback, and responding to market requests. REGENHU’s customer-oriented approach is embedded in its product and design philosophy. Launched in November 2020, the R-GEN 100 has already been implemented in major universities and research centers worldwide. The traction for this instrument is growing faster.