High throughput XRF spectrometers like the Rigaku ZSX Primus and Simultix series are the workhorses of industry and academia, used in applications such as mining, mineral processing, cement and metal manufacturing. Commonly equipped with large sample trays, they can run continuously to support industrial processes and play a critical role in quality and process control, feeding data back into the system ensuring production remains within specification. For this reason, maximum up time and accuracy as well as minimum maintenance e.g. recalibration is essential. This is where tube above XRF spectrometers excel.

Although WDXRFs are more expensive, they are typically preferred in industrial processes over EDXRF spectrometers for their higher resolution and ability to better resolve spectral lines, as well their superior light element sensitivity.

Tube Above vs Tube Below XRF Optical Configurations

While manufacturers may claim various points of difference, WDXRFs can be broadly broken down into 2 types of optical configurations:

Tube above configuration

Tube below configuration

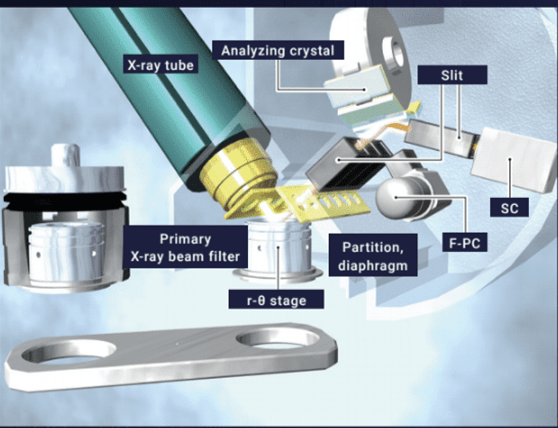

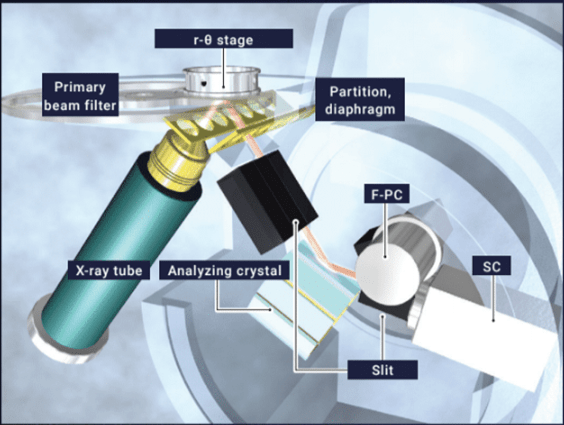

Schematic representation of the tube above (left) and tube below (right) optical configurations used in WDXRF spectrometers.

While the name specifically refers to the location of the X-ray source (tube) location in relation to the sample, it actually refers to the entire optical component layout.

Why Tube-Above Optics?

The benefits to the tube-above configuration which will be discussed herein. These benefits relate to the XRF’s application as a critical part of the manufacturing workflow.

Better for Pressed Pellets

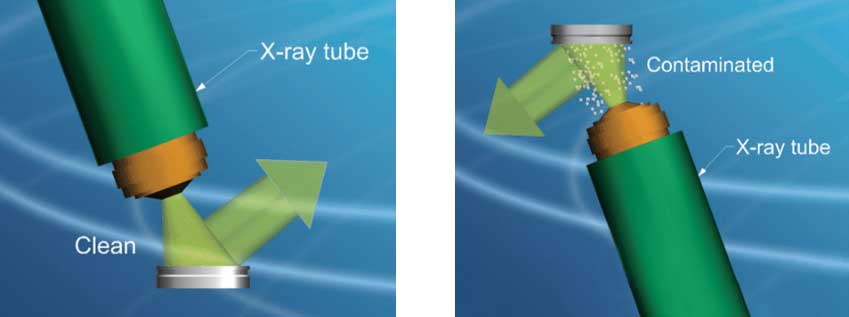

Pressed powder samples offer a fast and cost effective sample preparation method for XRF. Pressed pellets may or may not use a binder to help hold the powder particles together. Either way, it is still possible for the pressed pellet to fail or break into pieces, especially during the evacuation process. In such cases it particles may be deposit on the X-ray tube window or detector Be window which can skew future readings. If this happens cleaning these delicate optical components should only be performed by a trained engineer.

With a tube-above system (left) there is no impact on the optical components due to loose particles falling from poorly prepared samples, whereas precision components can be contaminated in tube-below systems.

As can be seen from the figure above, the tube above configuration is not at risk of contamination from loose particles, ensuring accuracy of measurements and virtually eliminating the possibility of needing a service engineer to clean optical components.

Better for Fused Beads

On the rare occasion, fused beads can shatter. The resultant fragments are generally quite hard. As such, these fragments may cause considerable damage to the “softer or thinner” parts of the X-ray spectrometer, e.g. X-ray tube window (which needs to be ultra-thin for ultimate light element sensitivity), detector foils and potentially even analyser crystal surfaces.

In such an event, a service engineer visit may required to bring the system back online. This results in added expense, downtime, possibly loss in production and consequently an impact on the bottom line.

Using a tube above configuration avoids this possibility altogether with any sample fragments simply falling into the sample holder and not entering the inside of the spectrometer.

Safer for Liquids

If you need to measure liquids, the tube above configuration is a much safer option, in particular if the liquids in question are oily or corrosive. In the event of a spill or leak, important optical components are not at risk of being coated or contaminated. In fact, in the event of a leak, the cleanup can often be accomplished without the need to call in a service engineer, minimising costs and downtime.

Liquid sample holder for XRF with tube-above configuration.

Better for Dust

The reality is, most industrial applications using XRFs aren’t using them in cleanrooms, so dust is unavoidable. Consequently, dust can make its way onto samples and into chambers and the last place you want it is on your detector.

Over time, this dust can build up on your detector and gradually throwing out you readings more and more. Meanwhile, you are relying on data from your XRF to control your process and you are mistakenly, inaccuratrely compensating in your process based on this “contaminated” data. Alternatively, you send samples out for independent testing and you realise your XRF data is out, requiring a recalibration. Either way, not an ideal situation which could be avoided with a tube-above system.

Tube Above XRF Spectrometers

Rigaku currently offers a number of WDXRFs with the tube-above configuration. These include:

High-speed simultaneous XRF

High-power sequential WDXRF

Affordable sequential WDXRF

These systems all use the latest technology analysing crystals to ensure you get the most accurate data. It may surprise you to know that Rigaku manufactures the most high-tech analysing crystals which are also found in other brands of XRFs.

Next Time You Buy an XRF

Now that you are aware of the benefits of tube above XRF’s, do yourself a favout and ask about a tube above system, especially for industrial processing where XRF analysis is an integral/critical part of a manufacturing workflow. In particular, if you are analysing pressed powder or liquid samples, you really need consider a tube-above XRF spectrometer to ensure no dust, particles or spilled sample are depositing and building up on important optical components, potentially skewing your data.

The advantages of tube-above XRF spectrometers are obvious for pressed powder analysis. For those who analyse fused beads or even liquids, there are also benefits to using tube-above XRFs that should not be ignored.

Furthermore, when weighing up options for your next XRF purchase, remember X-ray tubes have a finite lifespan, and you will no doubt go through a few during your spectrometer´s lifespan, so this should be factored into your running costs/operational expenditure budget.

X-ray tubes are at the very heart of your instrument, so don’t forget to ask about:

- X-ray tube lifespan

- X-ray tube stability

- Replacement costs

when specifying your next XRF system.